Pros and Cons of Concealed Fastener Wall Panels

Like it or not, every decision we make involves give and take. This idea of pros and cons certainly holds true when choosing between concealed and exposed fastener metal panel systems.

Pros

Aesthetics is one of the primary benefits of concealed fastener panels. The clean look of walls without fasteners everywhere appeals to many building owners. Additionally, designers appreciate unlimited opportunities to combine panels of different widths, lengths, and colors to turn form and function into art.

Additionally, many concealed fastener panels can install horizontally, which provides a unique and high-end feel at a much more attractive price than other product options. Designers also like the flexibility to combine vertical and horizontal panels to create architectural interest, as shown in the image below.

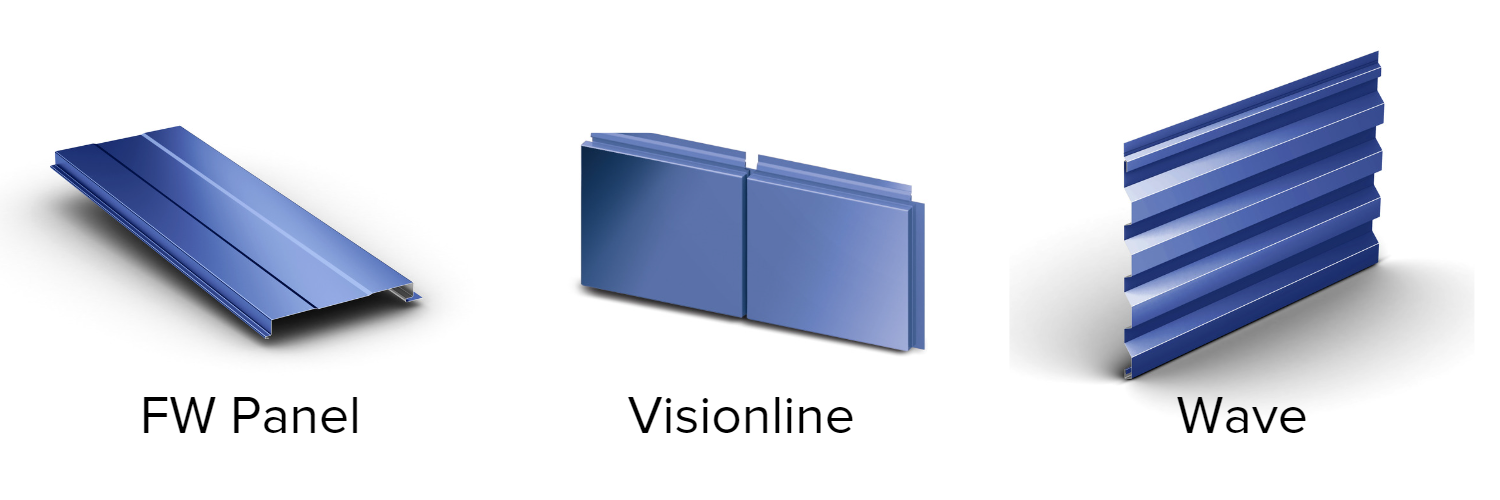

The options for different shapes of concealed fastener panels also vary greatly from their exposed fastened counterparts.

Reduced opportunity for leaks at fastener locations is another benefit of concealed fastener panels. Admittedly leaks in wall applications are much less frequent and problematic than in roofing applications; however, they can be equally challenging to identify and repair. Consequently, many discerning owners prefer to avoid the small risk that using fasteners present.

Additionally, the use of any visible fastener introduces maintenance to the project. While the gasketed material in fastener washers has dramatically improved, fastener replacement is still realistic after a couple of decades. Using concealed fastener panels completely avoids any maintenance at the fastener location.

For many owners, enhanced security is another benefit of concealed fastener systems. While not much will stand in the way if someone’s determined to gain entry, concealed fastener systems make it more challenging than their exposed fastened counterparts.

Cons

As mentioned earlier, every choice we make involves give and take. While concealed fastener panels offer improved aesthetics, design flexibility, and security with less maintenance, they present some drawbacks.

While they cost significantly less than other product options, concealed fastener panels cost more than their exposed fastened counterparts. Consequently, cost represents a primary downside of concealed fastener panels for some owners and designers. Panel style and reduced cover width impact the cost of both the product and installation.

The narrower width of concealed fastener panels means it takes manufacturers longer to produce the same amount of product, so the product sells for a higher price per square foot. Additionally, most concealed fastened systems ship in solid wooden crates to avoid shipping damage.

Beyond the cost and labor necessary to build the crates, this packaging takes up more space during shipping, increasing freight costs.

The narrower panel width of concealed fastened systems also impacts installation costs and job completion speed since crews often handle twice as many panels to install the same square footage.

While many building owners crave the clean look of concealed fastener panels, oil canning can be an issue for this product family. While narrower panel widths, heavier gauges, and pan conditions like striations can help minimize the phenomena, it’s vital to ensure the smoothness and levelness of the substructure because steel often acts like a mirror and telegraph inconsistencies. In contrast, exposed fastener panels can be more forgiving.

Lastly, repairing concealed fastener systems can be more challenging than exposed fastened panels. The modifications can typically still be accomplished; however, most concealed fastener panels' interlocking nature makes it more difficult.

So which is the best panel for you? Deciding between concealed and exposed fastener panels boils down to your project specifics, desired aesthetics, cost, and appetite for maintenance. Contact us if you’d like to chat about your project specifics. We’re always here to help!

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.