Concealed and Exposed Fastener Roof Panels-Which is Best for Your Customer?

As a contractor, you wear many hats and answer many questions from both crews and your customers. Chances are good you can answer many in your sleep while others, like making product recommendations, require a little more thought.

Let’s face it; if all of your customers and prospects had the same project specifics, budget, expectations, and timeline, you could probably handle product recommendations in your sleep too.

Let’s face it; if all of your customers and prospects had the same project specifics, budget, expectations, and timeline, you could probably handle product recommendations in your sleep too.

Unfortunately, we all know that’s not realistic. Instead, everyone wants something different and for different reasons. Consequently, the balancing act involves knowing the specifics and priorities of each customer so you can make the best recommendation.

To that point, we’re often asked about the differences between concealed and exposed fastener roof panels and how to determine which to recommend. The short answer is, there’s not a clear winner because they each excel in different situations. Let’s look at the two most important topics, life expectancy, and cost, to understand further.

Life Expectancy

Panel Length: Metal panels expand and contract due to the ambient air temperature. This phenomenon is known as thermal cycling, and it’s worse in parts of the country that experience extreme temperature swings, both hot and cold.

Longer panel lengths are also a factor when calculating the potential effect of thermal cycling because longer panels experience more significant movement in both directions than shorter-length panels. This technical bulletin by our engineers shows that a 130’ long panel can move approximately 1.5” in some geographic locations as temperatures change throughout the day and season. The clips used in standing seam systems typically allow for expansion and contraction; however, exposed fastener panels do not.

Instead, the fastener pierces the panel during installation and effectively “pins” the panel. And as thermal cycling occurs, exposed fastener panels’ ability to move is limited. For panel runs less than 40’, it’s usually not an issue. However, in longer runs, the panel’s consistent expansion and contraction can wear the steel away and elongate the fastener hole.

When this occurs, the watertightness of the building can be compromised. Consequently, it’s important to factor the building size and associated panel length into the decision of whether to recommend exposed or concealed fastener panels to your customers.

Fasteners: It’s also important to realize that the fasteners used to attach exposed fastener panels impact the roofing system’s life expectancy (or, at a minimum, the required maintenance) in several areas.

First, the screw used to attach the panel relies on a neoprene washer under the head of the screw to seal the entry point and prevent water and snow from entering the building. Over time, sun, wind, snow, and rain can cause the neoprene washer to shrink and lose its effectiveness, ultimately allowing moisture to penetrate the building.

It is important to realize that this situation isn’t typical until the year 20-30, and even then, it’s easily remedied by simply removing and replacing the fasteners. Still, you can’t deny that exposed fastener systems introduce the need for future maintenance.

Secondly, the thermal cycling phenomena addressed earlier can also cause screws to back out of the panels and substrate. Metal roofing with loose or missing fasteners can suffer reduced wind resistance and even possible moisture intrusion. Consequently, it’s essential to regularly inspect exposed fastener roofing systems and perform any necessary repairs as soon as possible.

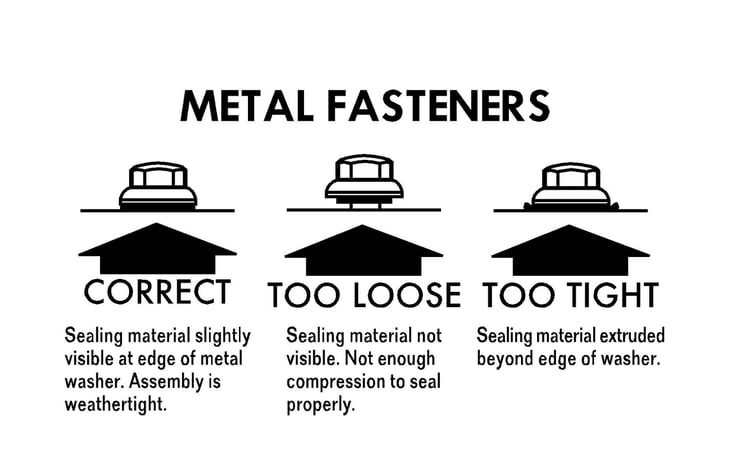

Lastly, it’s important to realize that errors made during fastener installation can compromise the building’s weather tightness from day one. The three most common installation errors for fasteners occur when screws are either misaligned, overdriven or underdriven.

As the image below shows, each mistake can allow water to enter the building because the washers aren’t properly seated. Consequently, if you recommend exposed fastener roof systems, it’s important to ensure your crews are properly trained and supplied with the proper equipment.

Paint: For customers with life expectancy high on their priority list, you’ll always want to go with the best possible paint system. Standing seam (or concealed fastener) panels routinely use a PVDF-based coating system under the Kynar 500® or Hylar 5000® trade names. In contrast, some manufacturers use a lesser quality Silicone Modified Polyester paint system for their exposed fastener panels. Silicone Modified Polyester paint systems are much more susceptible to fade and chalk and have a shorter life span.

At McElroy Metal, we’re proud to offer Kynar 500/Hylar 5000 paint systems for both our concealed and exposed fastener panels, so you are covered either way on this front. If you’re not working with us, make it a point to talk with your manufacturer to learn the paint system they’re supplying for both panel types and factor that into your product recommendation.

Remember, if you’re working with a customer who places a high priority on life expectancy, you’ll want to be sure to recommend a Kynar 500 product regardless of whether it’s a concealed or exposed fastener panel. You can read more about the differences between Kynar and Silicone Polyester paint systems here.

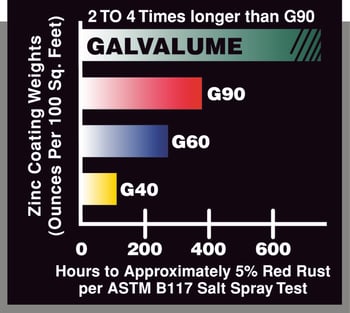

Substrate: Beyond the paint, the substrate (or the base metal under the paint) is also a factor. Most standing seam systems use a Galvalume substrate, where many exposed fastener systems have a Galvanized substrate.

Galvalume, invented by Bethlehem Steel in 1972, is a combination of 43.5% zinc, 55% aluminum, and 1.5% silicone. Its composition combines the sacrificial properties of zinc and the barrier protection of aluminum. Over four decades of testing and field applications have shown that Galvalume delivers superior corrosion resistance compared to Galvanized panels and is the preferred substrate for projects where long-term performance is essential. (See chart below)

Bottom line: if you’re dealing with a customer with an eye toward life expectancy, the substrate conversation might be equally (if not even more) important than concealed vs. exposed fastener systems.

Bottom line: if you’re dealing with a customer with an eye toward life expectancy, the substrate conversation might be equally (if not even more) important than concealed vs. exposed fastener systems.

At McElroy Metal, we’re proud to offer Galvalume substrates for both panel types, but again, not all manufacturers approach things the same way, so be sure to ask about substrates. Also, if this isn’t a strong area for you, you might want to learn more about substrates here.

Cost Comparisons

Cost differences affect both labor and material when comparing concealed and exposed fastener roof systems.

Labor Differences

You should expect labor to be significantly higher for concealed fastener systems than for their exposed fastener panel counterparts. Part of the difference lies in the fact that concealed fastener panels (like standing seam panels) typically cover 12-18” whereas exposed fastener style panels frequently cover 36”. The example below highlights the impact panel width has on labor using the example of a 100’ long roof:

Consequently, your crews are handling twice as many panels in the concealed fastener application. Twice as many panels mean twice as many interruptions to stand up, move from their position to grab another panel, get back in place to install, ensure panel squareness and modularity, etc. Your labor bid for concealed fastener panels should reflect that added cost.

Material Cost

While we’ve already addressed that your labor should be higher for standing seam panels than exposed fasteners, it’s important to realize that material costs will also increase. Standing seam panels are typically produced from heavier gauge materials, require more packaging, higher freight costs, in-seam sealant, and slower line speeds during production, so they will always cost more than exposed fastener systems. To learn more about the specifics, give our post, “Why is Standing Seam Metal Roofing So Expensive” a read.

Summary

In closing, when making recommendations on exposed vs. concealed fastener systems, it’s important to consider the panel length, paint system, budget, and the owner’s appetite for ongoing maintenance.

Admittedly standing seam panels are a more expensive option than exposed fastener roofing panels. Yet, they're absolutely the better recommendation for owners with a strong desire for a once-and-done roofing approach.

But does that mean they’re the right product for everyone? Absolutely not. For panel runs below 40’ and owners who prioritize budget over ongoing maintenance requirements, exposed fastener panels can be a solid recommendation.

Still have questions, don’t hesitate to contact us. We’re always here to help!

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.