What’s the Best Exposed Fastener for Residential Metal Roofing?

We’re often asked which fastener we recommend for exposed fastened residential metal roofing projects.

The reality is that the substructure the fastener goes into is a more critical consideration than whether it's a residential or commercial building.

Wood Purlins

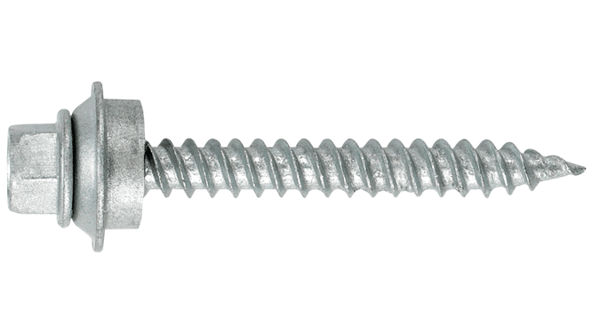

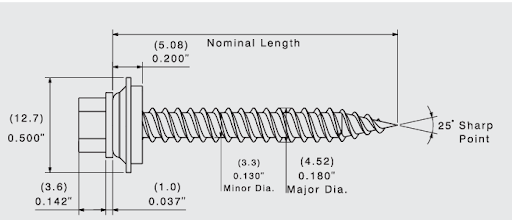

When attaching metal panels to wood purlins, such as a typical 2” x 4”, a #9 fastener offers good pull-out values at an economical price.

This type of fastener has the following specifications:

- 15 threads per inch

- .180” Diameter

- Self-drills through steel up to 24 Ga. thick

- Offers a 542 lbf pull-out value when it penetrates the wood purlin by at least 1.”

Photo and graphic courtesy of SFS

OSB/Plywood Decking

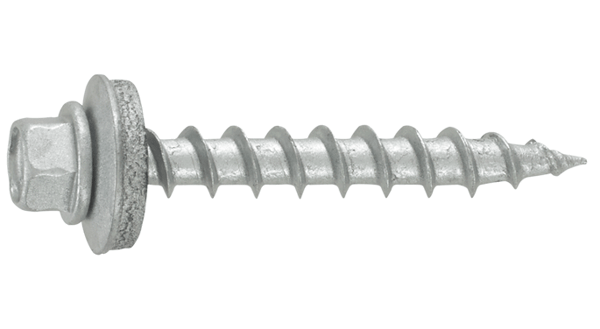

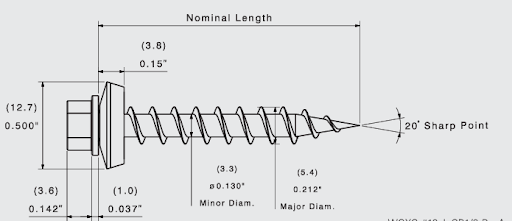

Switching from wood purlins to OSB or plywood decking changes the fastener recommendation from a #9, as discussed previously, to a #12.

This type of fastener has the following specifications:

- 8 threads per inch (almost half of the #9 discussed above)

- .212” Diameter (15% thicker than the #9 discussed above)

- Self-drills through steel up to 24 Ga. thick

Photo and graphic courtesy of SFS

Photo and graphic courtesy of SFS

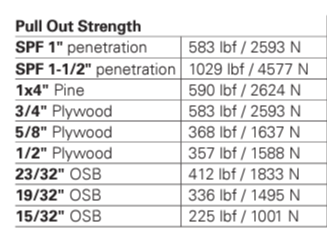

Pull-out values will vary significantly based on decking type and thickness, as illustrated in the chart below:

Graphic courtesy of SFS

As you can see in the chart above, ¾” plywood offers a 583 lbf pull-out value while ¾” OSB drops to a 412 lbf value. That equates to 30% lower performance when the same fastener is installed into a different type of wood substrate.

What’s the Downside to Using a #12?

Given the larger shank diameter and thread style, #12 fasteners cost approximately 25%-30% more than #9 fasteners. While the cost is higher, once educated, most consumers can easily justify spending a few hundred dollars more on the overall project budget to gain greater pull-out values.

In rare cases, availability can be an issue. Given the overwhelming data, most manufacturers inventory both #9 and #12 fasteners to offer their customers proper product selection.

Additional Considerations

- A #12 screw also works well for wood 2” x 4” purlins

- Currently, #9 & #10 screws represent 75% of SFS sales, while #12 represents 25% of their volume. However, as contractor and customer knowledge increases, #12 screws continue to gain market share.

- Some engineers believe that using a #12 fastener also helps reduce the risk of screw shear. Screw shear happens when thermal expansion and contraction of the roof panels cause the fastener head to pop off. When this occurs, the screw shank remains in the roofing system, but there is no cap or washer to seal the opening.

Summary

Not all “wood” substrates offer the same pull-out values. Consequently, education is vital. Manufacturers and contractors must educate building owners on the importance of selecting the most appropriate fastener for the substrate and project instead of the cheapest or most common.

If you’d like help to determine the best fastener for your next project, contact us, we’re always here to help!

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=767&name=What%20to%20Expect%20When%20You%20Order%20From%20McElroy%20Metal%20(1).png)

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.