Metal Roof Paint Systems: Kynar 500® vs. SMP

Once you’ve made decisions about your metal roofing material and contractor, the roof paint or coating system you choose might not seem like a difficult decision to make. But a roof is a long-term investment, and the paint/coating system is the difference between a roof that only looks good now and a roof that looks good for the long term.

Before we compare specific paints, it’s important to understand some of the basic paint characteristics and terms used in metal roofing. If you’re new to paint systems for metal roofing, we’d recommend checking out this article from MetalCon for a good introduction to all things paint.

Paint Basics

All paints have three basic components:

- Pigment – the part of the paint that creates the color and reflects UV rays

- Resin – resin holds the pigment together and provides most of the film properties

- Solvent – this part of the paint will evaporate during the curing process

The composition of these three components has a direct correlation to paint performance. More specifically, these components affect film integrity and the ability to resist fading and chalking, which are the biggest determining factors for how the paint will perform on your new roof.

When comparing roofing paint systems, there are three common types of paint in the metal roofing industry:

- Polyester (Good)

- Silicone Modified Polyester (Better)

- Fluoropolymer/PVDF (Commonly referred to as Kynar 500® (Best)

Polyester (Good)

Polyester paints were the paint of choice in the 1980s. While the low price of polyester paint might seem attractive to homeowners today, its performance doesn’t compare favorably to other paint options.

Polyester paint is hard and resistant to scratches, but without silicone, it is prone to chalking. The lack of silicone also means that the paint's new, glossy appearance fades quickly.

Polyester paints are the lowest-performing paints today, with the lowest price point. So, while still available, polyester paint is the least popular option for homeowners using metal roofing today.

Silicone Modified Polyester (Better)

Silicone Modified Polyester (SMP) paints are a middle-of-the-road option for metal roofs and offer a mid-level price point and mid-level performance.

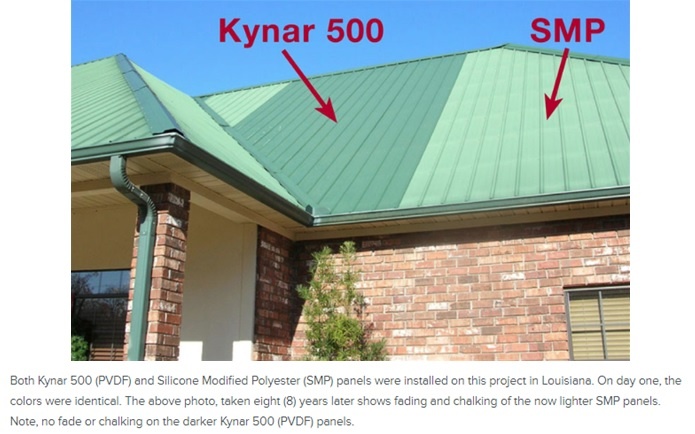

This paint style typically contains 30% silicone in the resin portion of the paint (initially, silicone levels were higher, but it was determined to be unnecessary to gain the desired performance). This means that the initial and long-term gloss of the paint is superior to that of polyester paint systems. The silicone also allows for better resistance to fade and chalk than polyester counterparts. However, SMP paint systems still perform at a lower level than Kynar 500® systems.

There are two major drawbacks to SMP paint systems. First, the quality varies greatly between manufacturers depending on the type of pigment used (ceramic systems outperform organic and inorganic type systems). Second, because of the hardness of this style of paint, these paint systems can micro-fracture during metal roof panel manufacturing. Once fracturing occurs, the base metal is exposed to the elements, and rusting/failure can begin. At McElroy Metal, we use Thermoforming technology to reduce the risk of this phenomenon.

So, while SMP paint systems are better than polyester paint systems and are the most widely used, they aren’t the best metal roofing option available to homeowners today.

Fluoropolymer/Kynar (Best)

Offering the best protection against fade and chalk, Fluoropolymer/PVDF coatings are the industry’s best-performing paint system. The trade name for this type of coating is Kynar 500®, a chemical cousin to Teflon™. To be classified as a Kynar 500® coating, the PVDF component (Polyvinylidene fluoride) must be 70% of the total resin content. While Kynar 500® paint systems are a bit more costly, they offer unparalleled performance.

Developed in the 1960s, Kynar® was initially produced by a single manufacturer for use on historic and monumental buildings. However, over time more manufacturers began producing Kynar paint systems, and the price fell to a level that made it accessible to homeowners.

Kynar 500® paint systems are a softer paint than SMPs so the paint is more flexible. This means that it is less likely to fracture during panel manufacturing than SMP counterparts. This paint style also offers superior chalk resistance, fade resistance, gloss retention, and film integrity.

This building dramatically illustrates Kynar 500®'s superior performance. This building was built in two phases, nine years apart. Note that there is no color difference between the two halves of the roof. No fade! No chalk!

Comparing Paint Systems

When it comes to longevity and appearance, Kynar 500® outperforms both polyester and SMP paint systems. Kynar 500® typically adds a bit more to the material pricing than either of the other options. However, keep in mind that this is only a reflection on materials pricing, labor pricing remains unchanged so the overall price increase is often minimal. McElroy Metal is one of the only manufacturers that has taken a full-scale stocking position on Kynar 500® in the lighter gauges commonly used for residential roofing.

McElroy Metal sells both Kynar 500® and SMP coated panels so contractors that install McElroy Metal products have access to both coating systems. We highly recommend Kynar 500® coatings because we’ve seen outstanding results in long-term performance and customer satisfaction over the last two decades.

Learn More

View a full list of our Kynar 500® metal roof products, or contact us at any time to learn more about our roofing solutions.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.