What is the most cost-effective metal roof panel width to specify and why?

When contractors and specifiers evaluate metal roofing systems, panel width is often treated as a secondary detail, behind profile selection, slope capability, or attachment method. In practice, panel width can influence installation efficiency, material usage, and overall project cost. Understanding how width affects those factors early in the specification process helps teams make more informed decisions when balancing performance expectations with budget considerations.

Rather than focusing on a single "best" option, the goal is to understand when wider panels offer advantages and when narrower panels may be the more appropriate choice.

How Metal Roof Panel Width Influences Coverage

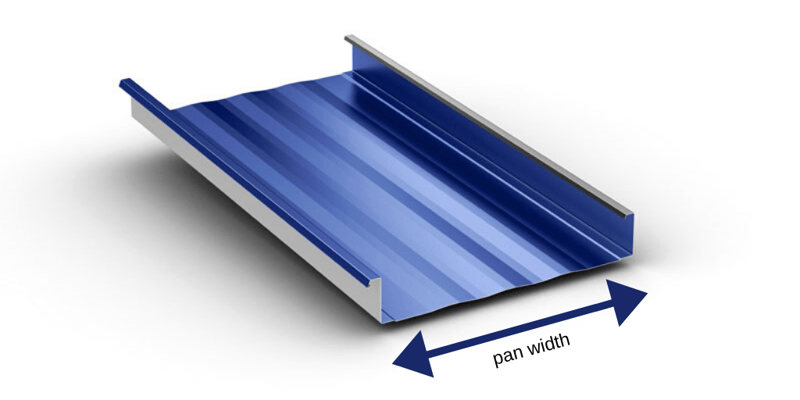

Standing seam metal roofing panels are commonly produced in widths ranging from approximately 12 inches to 24 inches, measured seam-to-seam. That measurement determines how many panels are required to cover a given roof area.

As panel width increases, fewer panels are needed to achieve the same coverage. While the difference between widths may appear minor at first glance, it becomes more significant as the roof size increases. Fewer panels generally result in fewer seams and fewer attachment points across the roof surface.

Why Wider Metal Roof Panels Are Often More Cost-Effective

One of the primary reasons wider panels are frequently viewed as more cost-effective is their efficiency during installation. Covering more area per panel reduces the total number of panels required, which can affect both labor and accessory usage.

The cost advantages of wider panels typically come from several related factors: fewer panels to install, which can reduce overall installation time; fewer clips, fasteners, and seams required across the roof; and reduced repetition of installation steps, improving crew efficiency.

Even modest efficiencies at the panel level can add up on larger projects, making panel width an important consideration when evaluating total installed cost.

When Narrower Metal Roof Panels May Be the Better Choice

Although wider panels often provide efficiency advantages, they are not always the most appropriate option for every application. Roof slope, visibility, and appearance expectations can all influence panel width selection.

On steeper slopes or highly visible roof planes, wider panels may increase oil canning concerns. Oil canning is a visual characteristic and does not affect structural performance, but it can influence how the finished roof is perceived.

Panel width should also align with the intended system type and roof conditions. Mechanically seamed systems may accommodate wider panels effectively, particularly on low-slope or commercial roofs. Snap-together systems on steeper slopes may perform well at narrower widths without introducing unnecessary complexity.

Metal Roof Panel Width and Appearance Considerations

Oil canning is influenced by several interacting factors, not panel width alone. Understanding those influences helps set realistic expectations for the finished roof.

Factors that can affect the visibility of oil canning include panel width and flatness, color selection (particularly darker finishes), and surface treatments such as smooth versus lightly striated panels.

Because oil canning is cosmetic rather than structural, addressing it is typically a matter of finish selection and expectation management rather than system performance.

How Onsite Rollforming Fits Into the Equation

On larger projects, onsite rollforming can further improve installation efficiency, regardless of panel width. Producing panels directly at the jobsite allows for longer panel lengths, which reduces the number of end laps and can simplify installation sequencing.

Additional benefits may include reduced material waste and less packaging and handling compared to factory-cut panels. When conditions allow, onsite rollforming can support both installation efficiency and overall project flow.

Selecting the Right Panel Width for Your Project

There is no single panel width that is universally appropriate for every roof. The most cost-effective choice depends on how roof geometry, system requirements, appearance expectations, labor efficiency, and logistics interact on a given project.

In many cases, wider panels offer clear efficiency benefits. In others, narrower panels may better align with roof slope, visibility, or design intent. Evaluating these trade-offs helps ensure that the selected system meets performance requirements without unnecessary complexity.

Final Thoughts on Cost-Effective Metal Roof Panel Width

Panel width is more than a dimensional specification. It influences how efficiently a roof is installed, how it looks once complete, and how project costs are managed. By understanding the tradeoffs between wider and narrower panels early in the design process, contractors and specifiers can make decisions that support both performance and long-term value.

Thoughtful panel width selection helps align expectations, streamline installation, and deliver a roof system that performs as intended throughout its service life.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=767&name=What%20to%20Expect%20When%20You%20Order%20From%20McElroy%20Metal%20(1).png)

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.