What are R-Panel Roofing and Standing Seam Roofing? And How Do They Compare?

Many options are available to building owners faced with choosing a new roof. Consequently, finding the right roofing system to meet the building’s longevity, durability, and aesthetic goals is essential. Two options available to building owners for new construction and retrofits are R-Panel roofing and standing seam roofing.

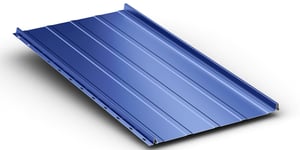

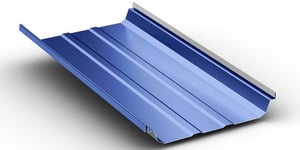

What is R-Panel Roofing?

R-Panel is a generic industry term used for a metal roof or wall panel with ribs 1 1/4" tall spaced at 12" on-center. This panel style offers a 36" wide coverage and attaches to the building substructure with exposed fasteners.

Initially, R-Panel profiles were used almost exclusively in the pre-engineered metal building industry. Over time, however, R-Panel has also become quite popular for residential roofing, especially in the southwest.

It is essential to realize that tens, if not hundreds, of different companies manufacture R-Panel. While they all produce a product that matches the basic specifications above, the quality levels can be anything but similar.

Two common differences to consider involve the panel gauge and paint system. At McElroy Metal, we're proud to offer our R-Panel in 26 & 24 gauge and two different paint systems. We recommend our Kynar 500® paint system for projects with long-term performance requirements; however, we also provide a silicone-modified polyester system (SMP) for cost-sensitive projects. If you aren't familiar with the differences, you can learn more about the paint systems here.

Beyond paint systems and panel gauges, the quality of the actual roll-forming equipment can vary greatly. While it might not seem obvious, tooling quality affects everything from panel appearance to ease of installation and performance.

Some smaller roll-formers (often called regional roll-formers) produce R-Panel from tooling that doesn’t offer the necessary panel length and width control. Still, others struggle to match the crispness of the panel ribs that other, more high-end manufacturers provide.

Bottom line: Unfortunately, not all R-Panels are created equal. Consequently, it’s essential to ask questions regarding panel thickness, paint systems, and tooling quality before selecting a manufacturer for R-Panel products.

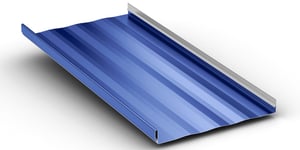

What is Standing Seam Roofing?

Standing seam metal roofs are typically installed vertically and run from eave to ridge. Standing seam systems feature a raised interlocking seam that connects adjoining panels and is popular in commercial, residential, and industrial settings.

Standing seam systems are installed with hidden clips and fasteners, eliminating visible fasteners that are more prone to leaking over time. As a result, some standing seam systems often offer what is called a weathertightness warranty. These warranties are designed to assure building owners that their building will remain leak-free for a specified period, often 20 years.

R-Panel Roofing vs. Standing Seam Roofing

Cost Comparison

In comparing the two systems, it’s essential to realize that R-Panel is widely available, often offers a shorter lead-time, and is more economical to purchase and install than standing seam systems. Part of the difference lies in the design differences between the panels.

R-Panel covers 3’ whereas standing seam products more often cover 16-18”, meaning it takes two standing seam panels to cover the duplicate square footage as one R-Panel. Two panels vs. one affect everything from panel production at the manufacturer to packaging, transportation, and even crew installation, so the difference in panel width is significant.

R-Panels also use exposed fasteners for attachment, whereas standing seam panels utilize clips and hidden fasteners. While that difference might seem minimal, it impacts cost. The clip is an additional cost to standing seam systems, but clipped systems also install more slowly than an exposed fastener panel like R-Panel.

Durability Comparison

Given the higher product and installation costs, you might wonder why any owner would choose standing seam products over an R-Panel style. The downside of R-Panels is that expansion and contraction can cause the fasteners to “slot” over time and wear away a bit of the metal. When this occurs, water can enter the building. Once this happens, owners choose to either replace the screws with an oversized fastener to cover the elongated hole or remove and replace the panels.

While that isn't an ideal situation from either a cost or maintenance perspective, it is essential to realize that expansion and contraction are functions of thermal cycling. Consequently, the phenomenon worsens in areas of the country that experience large temperature swings. It's also noteworthy that thermal cycling doesn't typically affect panels under 40' long. So for building owners with panels below 40' or those located in areas where temperature changes are minimal, it can be a non-issue.

Conversely, fasteners don't pierce standing seam panels during installation. Instead, a clip is commonly attached to the substructure, and the panels then engage with the clip. This clip allows for much more significant expansion and contraction than an R-Panel or any other exposed fastener panel can accommodate. Since there are no exposed fasteners in a standing seam roof system, thermal cycling (or expansion and contraction of the panels) doesn't limit the system's life expectancy.

Summary

Summary

While standing seam systems cost more to purchase and install, many owners find the enhanced durability, reduced likelihood of leaks, and minimal maintenance worth the extra cost.

Standing Seam Systems

Throughout this article, we’ve referred to R-Panel and standing seam panels as similar but different things. But that’s an unfair comparison. R-Panel is a specific panel type where the standing seam represents an entire product family.

While standing seam products are similar in their attachment method, there are numerous profiles and applications for standing seam panels. Although the different panel types can work on virtually any building that meets the required roof slope, there are certainly some more common products by industry segment.

Popular Residential/Light Commercial Products

Meridian: Meridian is our most economically priced standing seam panel for projects with a solid deck and a minimum 3:12 slope. The system is less expensive because fasteners attach the panel to the substrate through a pre-punched flange instead of clips. This product is also more economical since our standard offering is produced from 26 gauge material instead of the heavier 24 gauge thicknesses typical for standing seam systems. Consequently, the Meridian product is popular for residential and light commercial projects.

Meridian: Meridian is our most economically priced standing seam panel for projects with a solid deck and a minimum 3:12 slope. The system is less expensive because fasteners attach the panel to the substrate through a pre-punched flange instead of clips. This product is also more economical since our standard offering is produced from 26 gauge material instead of the heavier 24 gauge thicknesses typical for standing seam systems. Consequently, the Meridian product is popular for residential and light commercial projects.

Medallion Lok: Our Medallion Lok profile is also a favored product for residential and light commercial buildings with a 1 ¾” rib height and in-seam sealant in the male/female leg. Medallion Lok, produced in 24 gauge, offers purlin spanning capabilities, widths ranging from 12-18”, and in many cases, a weather-tightness warranty.

Medallion Lok: Our Medallion Lok profile is also a favored product for residential and light commercial buildings with a 1 ¾” rib height and in-seam sealant in the male/female leg. Medallion Lok, produced in 24 gauge, offers purlin spanning capabilities, widths ranging from 12-18”, and in many cases, a weather-tightness warranty.

Popular Commercial/Industrial Products

238T: Our 238T panel is a symmetrical panel which means that the panel looks the same on both the right and the left side. This design allows panel installation from either direction, which helps reduce installation costs and minimize scrap. But perhaps the most significant advantage of a symmetrical panel system is that it offers individual panel replacement in the field of the roof. Consequently, due to its symmetrical design and individual panel replaceability, it is a top choice for owners who anticipate future building repairs, modifications such as curbs, or building expansions. Our 238T mechanically seamed system is available in various pan widths. Weathertightness warranties are commonly available for this panel type as well.

238T: Our 238T panel is a symmetrical panel which means that the panel looks the same on both the right and the left side. This design allows panel installation from either direction, which helps reduce installation costs and minimize scrap. But perhaps the most significant advantage of a symmetrical panel system is that it offers individual panel replacement in the field of the roof. Consequently, due to its symmetrical design and individual panel replaceability, it is a top choice for owners who anticipate future building repairs, modifications such as curbs, or building expansions. Our 238T mechanically seamed system is available in various pan widths. Weathertightness warranties are commonly available for this panel type as well.

Maxima: Our Maxima series offers a wide variety of options, including 1.5, 2, and 3” seam heights. Two of the heights (1.5” & 2”) can also be curved for radius applications. All of the various panel heights are mechanically seamed, and weathertightness warranties are commonly available. With the vertical leg design, this panel offers an improved aesthetic appearance over trapezoidal panels like our ML90/MasterLok FS. Consequently, it’s a favorite choice for architects and designers.

Maxima: Our Maxima series offers a wide variety of options, including 1.5, 2, and 3” seam heights. Two of the heights (1.5” & 2”) can also be curved for radius applications. All of the various panel heights are mechanically seamed, and weathertightness warranties are commonly available. With the vertical leg design, this panel offers an improved aesthetic appearance over trapezoidal panels like our ML90/MasterLok FS. Consequently, it’s a favorite choice for architects and designers.

ML90/MasterLok FS: With a 24” panel cover width and an option to snap or mechanically seam, our ML90 and MasterLok FS trapezoidal panels represent our most competitively priced standing seam panels that can span purlins up to 5’ OC. ML90 and MasterLok FS system use are common in less visual, low slope applications.

ML90/MasterLok FS: With a 24” panel cover width and an option to snap or mechanically seam, our ML90 and MasterLok FS trapezoidal panels represent our most competitively priced standing seam panels that can span purlins up to 5’ OC. ML90 and MasterLok FS system use are common in less visual, low slope applications.

Consequently, this product type has been a mainstay in the commercial/industrial and PEMB markets since the early 1960s. Given its trapezoidal shape, it is better suited to straight panel runs and projects without valley conditions. Consequently, weathertightness warranties may not be available for all projects with this panel type.

Summary

So which is the right product for your roof? Only you can decide that, but it’s essential to consider your appetite for ongoing maintenance vs. cost in your decision-making process. If cost is your predominant criterion, then R-Panels may be your best option.

However, if you’re interested in a longer-term solution with a lower likelihood of leaks, standing seam systems may be your best choice. If you’d like to discuss your specific project, contact us, we’re always here to help!

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.