Types of Standing Seam Metal Roof

Used for commercial, residential, and industrial applications, standing seam metal roofs (also commonly referred to as concealed fastener roof panels) are a versatile roofing option that offers building owners and homeowners many advantages like cost savings, durability, and a wide variety of design options.

Standing Seam Metal Roofs

Standing seam metal roofing systems are one of the many roofing options available. Typically, they are installed vertically and run from eave to ridge. Standing seam systems also feature a raised interlocking seam that connects adjoining panels.

This family of panels is installed with concealed (or hidden) fasteners. Since the fasteners aren’t visible, most people prefer the visual look of standing seam panels over their exposed fastened counterparts.

Beyond the improved appearance, standing seam panels offer less maintenance and a longer life expectancy since exposed fastener panels allow water to penetrate the building over time. You can learn more about the differences between the panel types by clicking here.

There are many different types of standing seam metal roof systems, so building owners have unparalleled options for finding the best product for their unique needs.

Types of Standing Seam Metal Roof

With so many panel options, product selection can feel a bit overwhelming. However, standing seam panels have three defining factors: how they attach, how they engage with each other, and the panel shape. With a better understanding of these criteria, product selection becomes much more manageable.

Attachment Methods

The attachment method for standing seam panels refers to how the panels are physically attached to the roofing deck, rafters, or purlins. There are two main styles of attachment: fastening flange and clipped.

Fastening Flange: As the name implies, this family of panels is attached directly to the roof deck by inserting a fastener through a slotted flange. The next panel then snaps on top and covers both the fastening flange and the screw. While this attachment style is the most economical standing seam panel to purchase and install, there are limitations.

Fastening Flange: As the name implies, this family of panels is attached directly to the roof deck by inserting a fastener through a slotted flange. The next panel then snaps on top and covers both the fastening flange and the screw. While this attachment style is the most economical standing seam panel to purchase and install, there are limitations.

These panels are typically unsuitable for projects requiring a weathertightness warranty and need a solid roof deck for attachment. Additionally, the slotted flange limits the expansion and contraction ability of the panels to around 45’. Consequently, these panels are best suited for residential applications and smaller light commercial structures.

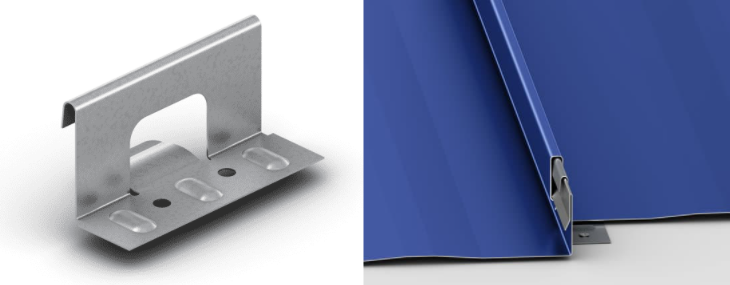

Clipped: Unlike fastening flange-style panels, clipped systems attach to the substructure with a heavy-gauge steel clip specifically designed to integrate with the panel's male/female legs.

While fastening flange systems require a solid deck, clipped systems typically install over either a solid deck or open framing like that commonly found in pre-engineered metal buildings. These clipped systems tend to offer more significant expansion and contraction features than fastening flange-style panels.

As a result, they are much better suited for the long panel runs commonly found in educational, commercial, and industrial applications. Based on the panel design and installation requirements, weathertightness warranties are common with clipped panel systems.

Engagement Methods

There are also two primary methods of panel engagement: snapped and mechanically seamed.

Snapped: As expected, the male/female legs on snapped panel systems snap in place due to their design. During installation, the vertical legs are positioned over each other, and pressure is applied to push the upper panel down onto the lower panel until the legs properly engage.

Typically, the snap condition is accomplished with simple pressure by hand, although sometimes a rubber mallet is also used. While it varies based on the panel design, some systems, such as ASTM E 1592, can meet rigorous uplift tests.

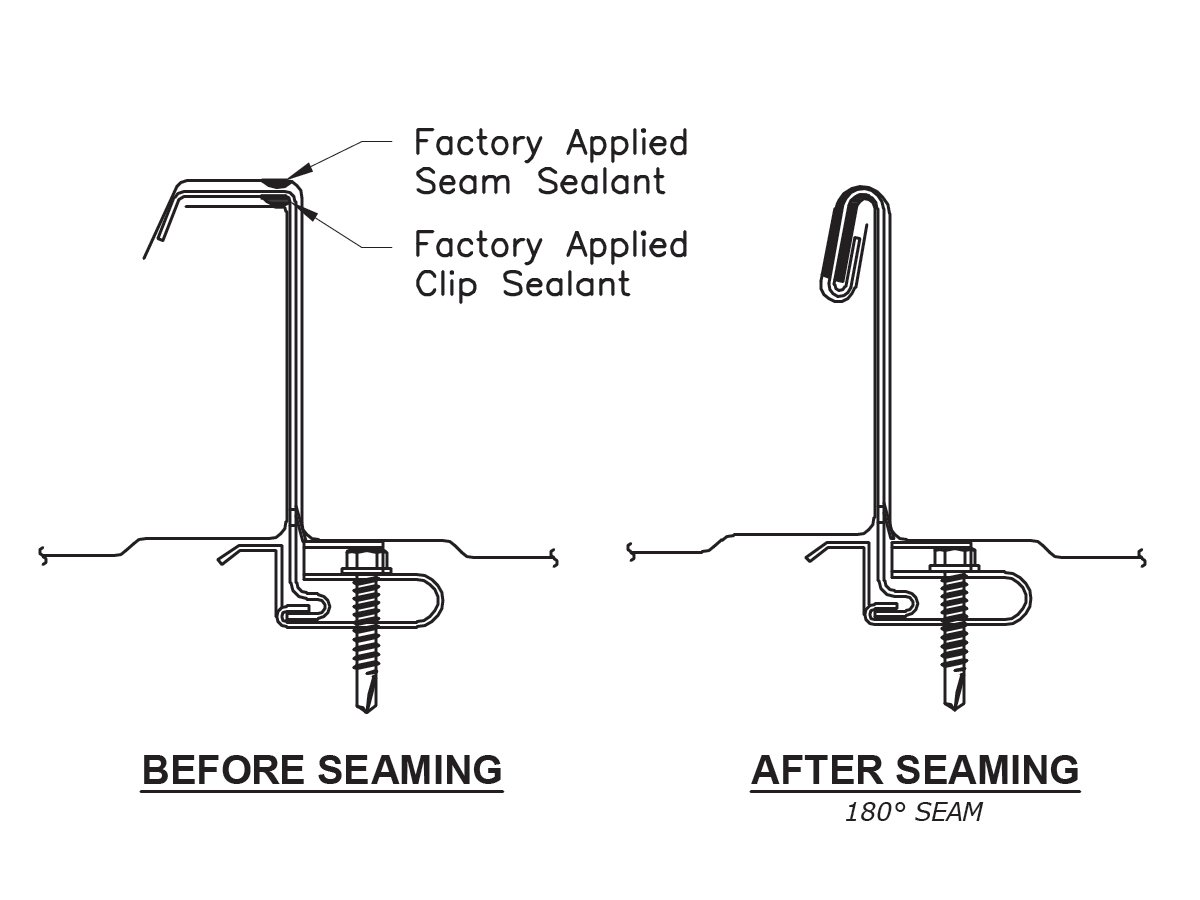

Mechanically Seamed: Unlike snapped panels, mechanically seamed panels require a motorized seaming machine to complete the installation and panel engagement.

During the seaming process, the mechanized machine folds two or more panel legs together, forming a much stronger connection than their snapped-style counterparts. Click here to view an installation video.

Mechanically seamed systems perform well on lower slope roof systems (think 2:12 and below), projects with high wind uplift, and stringent weathertightness warranty requirements. As a product family, they are routinely regarded as the best-standing seam panels available.

Seaming machines typically run between 30-50’ a minute. Based on panel design, seaming machines are considered either single or bi-directional. Single-pass seaming machines run only in one direction, most commonly from eave to ridge.

During this process, an installer usually engages the machine at the eave, and the machine pulls itself up the panel slope, completing the seaming process as it walks up to the ridge. Once the machine arrives at the ridge, someone disengages it and lowers it back down the center of the panel via a rope or similar device, where it is connected to the seam of the next panel.

Conversely, bidirectional seamers run from eave to ridge and ridge to eave. As you might expect, the seaming process is much quicker with bidirectional seamers (more than 50%) over single-direction seamers.

Symmetrical vs. Asymmetrical Panels

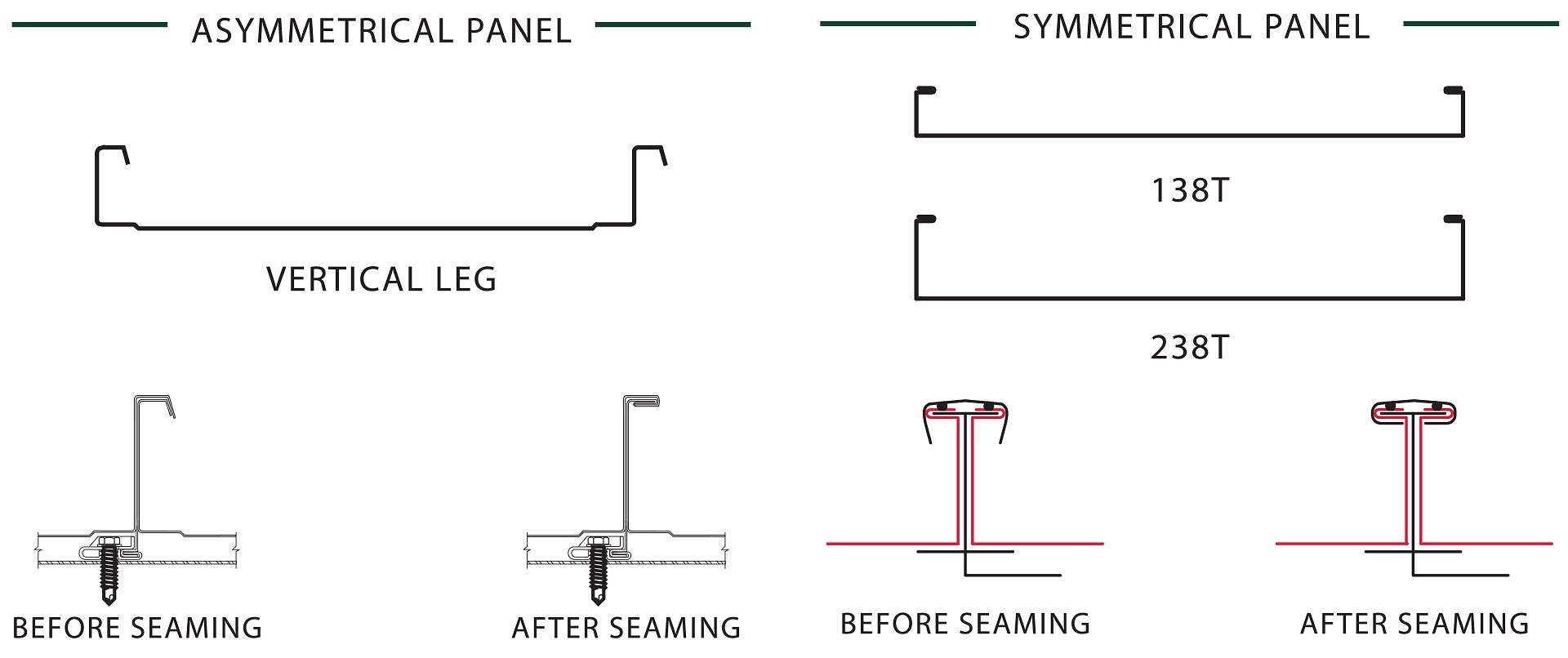

There are two main types of standing seam metal roofing panels available: symmetrical and asymmetrical panels. Symmetrical panels have the same legs on both the left and right sides. In comparison, the legs on asymmetrical panels are different. The panel design has implications ranging from install speed to cost and even future repairability.

Symmetrical systems, like the 138T and 238T roofing systems, lead the industry due to their significant initial and long-term savings. These savings stem, in part, from factors like labor savings, the reduced chance of damage from leaks, and ease of future repairs.

For starters, asymmetrical panels must be installed from one end of the building to the other in a one-by-one sequence. However, the installation of symmetrical panels starts at any point on the roof. This difference means installers can skip over penetrations and come back to them later or even have top installers work on intricate details.

At the same time, the rest of the crew continues sheeting the roof when working with a symmetrical panel system. This flexibility during installation leads to a higher-quality roof system.

Symmetrical panels also have less scrap and reduced costs than asymmetrical panels because installers can use the drop cut-off of one panel on the opposite side of the roof plane.

Symmetrical standing seam panels are also the best option for guaranteeing the ease of future repairs, remodels, and additions. That’s because a Symmetrical standing seam system does not have a male and female connection.

Instead, the seams mirror each other, and a separate seam cap covers the symmetrical seams. This panel design allows for the easy removal and replacement of individual panels.

An un-seaming machine makes replacing a symmetrical standing seam panel easy. The machine walks the panel and opens the cap back to its original shape, leaving the panel undamaged. After the seam cap is removed, panels can be easily removed and replaced or reinstalled.

To view a video of the unseaming operation and panel removal, click here.

As you might expect, with the host of benefits offered, symmetrical standing seam systems can be more expensive than their asymmetrical counterparts. That’s why factors such as building design, local building codes, and the potential for future building modifications should always be considered when selecting a standing seam product.

Are you unsure which panel style is best for you? Contact us. We’re happy to learn about your unique situation and help you identify the most cost-effective and appropriate product.

Learn More

Standing seam metal roofs offer building owners all the advantages of a metal roof with a wide range of design options. Our eBook Need a New Roof? How Building Owners Reduce Cost with a Metal Roof explores the roofing options available to building owners, including standing seam roofing systems. Follow the link below to download your copy of the Need a New Roof eBook.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=767&name=REVISED%20-%20The%20Top%2010%20Reasons%20to%20Choose%20Metal%20Roofing%20for%20Your%20Commercial%20Building%20(6).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.