Use Metal to Deliver a Retrofit Industrial Roofing System

Pre-engineered metal building systems have been a preferred construction method for industrial applications for well over 50 years. In fact, there are literally billions of square feet of metal buildings across the United States and metal roofing is the predominate roofing material installed on these metal buildings. Metal is the most prevalent roofing material due to several factors including performance, longevity and life-cycle cost.The question for building owners is how to handle repairs and replacement for metal roofs that were improperly installed or have out-lived their decades-long service-life.

McElroy Metal has developed several methods to recover an existing metal roof using our symmetrical 238T standing seam roof system. Available systems include a patented, frame-less Metal-Over-Metal recover option that provides a low-cost retrofit solution over existing exposed fastened panels with ribs up to 1.5" tall. The 238T tall clip recover system provides a lightweight, long-term solution to existing exposed fastener metal roofs that have completed their service life at a cost that is competitive with single-ply recover and will last two (2) to four (4) times longer and ensure equal loading across the structure.

McElroy Metal has developed several methods to recover an existing metal roof using our symmetrical 238T standing seam roof system. Available systems include a patented, frame-less Metal-Over-Metal recover option that provides a low-cost retrofit solution over existing exposed fastened panels with ribs up to 1.5" tall. The 238T tall clip recover system provides a lightweight, long-term solution to existing exposed fastener metal roofs that have completed their service life at a cost that is competitive with single-ply recover and will last two (2) to four (4) times longer and ensure equal loading across the structure.

Symmetrical standing seam systems are easier and quicker to install than conventional, non-symmetrical panels. With symmetrical panels there is no need to start installation at the end of a building, rather panels can be installed in the middle of the roof and two teams can simultaneously install panels in both directions. Also, curbs can be easily jumped over and finished later. Most importantly, the symmetrical 238T roof system allows for individual panel replace-ability. Having a structural standing seam metal roof that is easy to repair in the event of damage is a tremendous benefit for building owners.

Longevity and extended service lives are one of the key benefits of metal roofing. Currently, Galvalume roofs are projected to last over 50 years. Much can happen to a roof in that time period, from storm damage to simply needing to add a new penetration into the roof. With a symmetrical 238T roof system, the roof can be disassembled with ease and reassembled using new panels or even the existing panels.

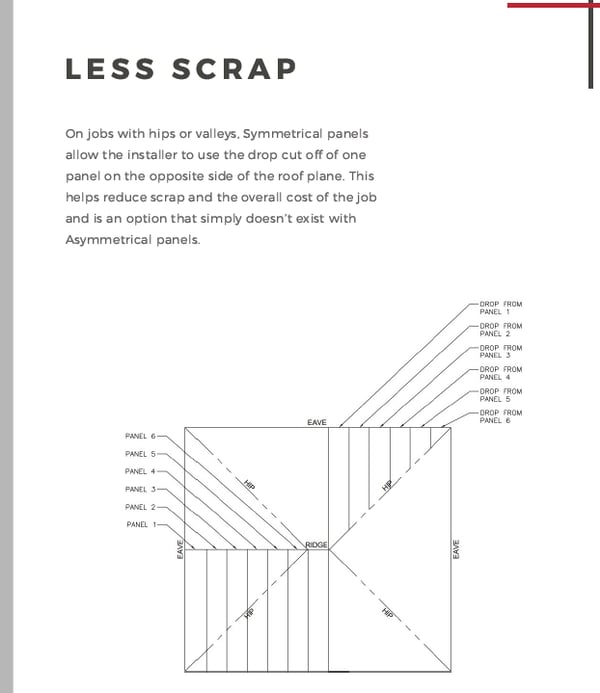

As explained below, scrap reduction is another benefit of symmetrical standing seam systems.

Here is a video of one of our 238T partners, Exterior Pro in Indiana installing a 238T Tall clip recover.

Symmetrical Standing Seam systems offers many other advantages, including

- Panels run from eave to ridge, eliminating leak-prone lap joints.

- Job site production/roll forming is available for long-length panels

- Individual panel replace-ability offers a huge benefit if panels become damaged from storms, trees or debris. Check out this video of our our panel un-seamer.

- Panels can be curved or tapered to meet aesthetic preferences

With all of these advantages, it is no-wonder that symmetrical standing seam systems are widely recognized as the industry's best option for retrofitting worn-out, existing metal roofs.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.