What is a Corrugated Metal Panel

Corrugated roofing and siding are widely recognized as the first metal panel profile to be developed and its origin goes back to England in the 1830s. In 1912, Trachte Brothers, Co from Madison, WI designed and patented a roll-forming machine to manufacture corrugated livestock water tanks. In 1919, Arthur Trachte utilized corrugated steel panels to build a structure to house his new Dodge automobile. Arthur’s new garage garnered considerable attention from friends and neighbors, so Trachte started selling garage packages. In those days, an 8’ x 16’ garage sold for $100.

From those humble beginnings, a myriad of other roofing and siding panel profiles have been developed that offer different aesthetic appeal, greater strength, and improved weather-tightness. However, the classic appearance of the early corrugated metal panel is still relevant and popular today. In fact, over the past 20 years or so, the use of corrugated panels has grown significantly as more and more people appreciate the classic and nostalgic appearance of old-style, corrugated panels.

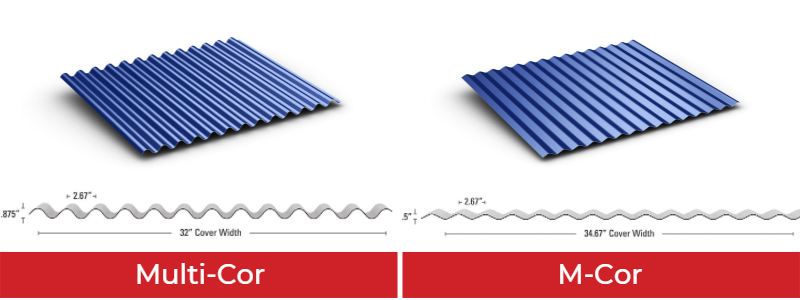

Corrugated panels are classified as exposed fastener panels, which means they are attached via fasteners that penetrate the panels and attach to the framing or substrate below. The appearance of corrugated panels can vary based on rib height and width. McElroy Metal offers two corrugated profiles.

Both Multi-Cor and M-Cor feature the classic “wavy” ribs that identify corrugated panels. Multi-Cor’s ⅞” high ribs are more pronounced/bold while M-Cor has a more subtle ½” high rib profile.

Versatility is another reason corrugated panels are popular. Panels are commonly installed as roofing panels, wall panels, interior accents, and liner panels.

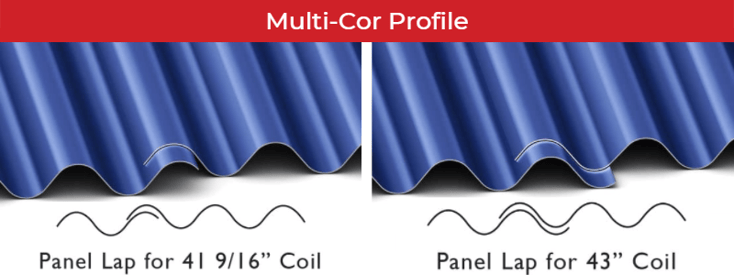

Manufacturing flexibility is another hallmark of corrugated panels. Due to corrugated panels’ consistent rib configurations, panels can be manufactured in a variety of widths, which is dependent on the coil size. This flexibility enables more options for substrate, colors, and gauges. It is important, however, to note that different panel widths will result in different lap conditions. To illustrate further, let’s take a closer look at 26-gauge Multi-Cor, which can be manufactured out of 41 9/16” or 43” master coil widths. A wider master coil will result in a wider Multi-Cor panel width, which will affect standard lap patterns as shown below.

For more information about laps as well as other information, such as fastener patterns, please see our Multi-Cor and M-Cor Product Data Sheets.

While the corrugated panel does allow for great flexibility, there are some limitations. For example, the simple, rounded lap does not contain any breaks or gaps that can help prevent leaks by inhibiting capillary draw. Capillary draw is similar to the concept of siphoning, where water can migrate between two layers of metal and result in a leak. Some newer styles of metal roofing, such as McElroy’s Max-Rib, have anti-siphoning drains or channels built into the panel design that helps stop siphoning water.

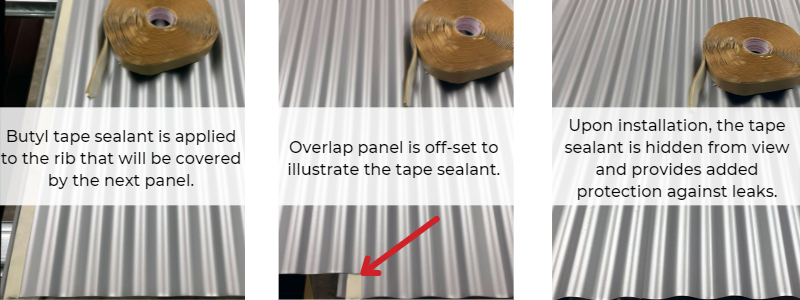

To improve weather-tightness, when corrugated panels are installed as roofing, butyl sealants should be applied to all panel laps. Butyl sealants are available in tube form or tape. Please see the images below for an example of how butyl tape sealant is applied.

While corrugated roof panels can be installed over open framing or solid decking, a best practice would be to install over solid decking and a high-quality underlayment, especially for residential applications.

Corrugated panels have surely withstood the test of time and remain popular today due to their flexibility and a unique, classic appearance. Although the panel design does have some limitations, proper installation techniques should ensure long-term performance equal to other exposed fastener roof and wall panels.

I'll help you create FAQs for the corrugated metal panel blog post. Let me search the project knowledge first to see if there's additional context that could inform these FAQs. Based on the corrugated metal panel blog post and the additional project knowledge, here are five comprehensive FAQs with detailed answers for roofing and construction professionals:

What Makes Corrugated Panels Different from Other Metal Roofing Profiles

FAQ 1: What makes corrugated panels different from other metal roofing profiles, and why should contractors consider them?

Corrugated panels represent the original metal roofing profile, and their enduring popularity stems from practical advantages. Unlike concealed fastener systems that require specialized clips and seaming equipment, corrugated panels use straightforward exposed fastener installation, making them accessible to contractors without extensive specialized training.

The classic wavy rib design offers immediate visual recognition and nostalgic appeal that resonates with many property owners. From a business perspective, corrugated panels offer exceptional manufacturing flexibility due to their consistent rib configurations, which enable production in various widths based on coil size. This flexibility provides contractors with more options for substrate materials, colors, and gauges compared to more restrictive panel systems.

Water Infiltration Prevention Techniques

FAQ 2: How do you prevent water infiltration issues with corrugated panel installations?

Weather-tightness represents the primary technical challenge with corrugated panels due to their simple, rounded lap design that lacks built-in anti-siphoning features found in newer profiles like Max-Rib. The rounded lap configuration can allow capillary draw, where water migrates between two metal layers through siphoning action.

To combat this, contractors must apply butyl sealants to all panel laps during roofing installations. Butyl sealants come in both tube and tape forms, with tape applications providing consistent coverage along lap joints. For residential applications, best practices include installing over solid decking with high-quality underlayment rather than open framing. This approach creates a secondary moisture barrier that protects against potential infiltration while maintaining the structural integrity of the installation.

Multi-Cor vs M-Cor Profile Specifications

FAQ 3: What are the key differences between Multi-Cor and M-Cor profiles, and how do they affect project specifications?

Both Multi-Cor and M-Cor feature the characteristic wavy ribs that define corrugated panels, but their rib heights create different aesthetic and performance characteristics. Multi-Cor's ⅞" high ribs deliver a more pronounced, bold appearance that works well for agricultural, industrial, and commercial applications where visual impact matters. M-Cor's ½" high ribs provide a more subtle profile that suits residential and architectural applications requiring understated metal roofing aesthetics.

The rib height difference also affects structural performance, with Multi-Cor's taller ribs providing enhanced strength characteristics for applications with higher load requirements. Contractors should consider the building type, architectural intent, and structural demands when selecting between these profiles to optimize both performance and visual appeal.

Panel Width Variation and Material Planning

FAQ 4: How does panel width variation affect installation planning and material ordering?

Manufacturing flexibility represents both an advantage and a planning consideration for corrugated panels. Multi-Cor can be manufactured from either 41 9/16" or 43" master coil widths, resulting in different finished panel widths that directly impact lap patterns and coverage calculations. Wider master coils produce wider panels, which affects the standard lap conditions and overall coverage per panel.

This variation requires careful coordination between contractors and manufacturers during the ordering process to ensure consistent lap patterns throughout the project. Contractors must verify the specific panel width being supplied and adjust their installation planning accordingly, particularly for projects requiring precise coverage calculations or when matching existing installations where panel width consistency is critical.

Installation Best Practices for Long-Term Performance

FAQ 5: What installation best practices ensure long-term performance for corrugated metal panels?

Successful corrugated panel installations begin with proper substrate preparation and fastening strategies. While panels can be installed over open framing, solid decking with quality underlayment provides superior long-term performance, especially for residential applications. Fastener selection and placement follow specific patterns outlined in manufacturer data sheets, with corrosion-resistant screws featuring neoprene washers preventing water infiltration at penetration points.

Proper fastener spacing prevents panel warping while maintaining structural attachment. Thermal movement accommodation becomes crucial since metal expands and contracts with temperature changes, requiring installation techniques that allow natural movement without compromising panel integrity. Flashing details at transitions, penetrations, and edges determine long-term weather resistance, making proper execution of these details essential for preventing moisture infiltration and ensuring warranty compliance.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.