The Facts About TPO Versus Metal Roofing Retrofits

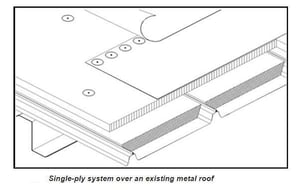

When you are making a presentation to any prospective customer interested in a metal-over-metal retrofit roof project, be sure to inquire if they are investigating other competitive products. Frequently you will discover they are getting pricing on a TPO overlay.

All things being equal, you are going to lose the price battle, typically between 20% -25%. In the scheme of things that’s not much but, if the customer “thinks” the products are equal you will be in a tough spot. The reality however is that the products absolutely are not equal by a long way!

Let’s look at a few very important differences:

Let’s look at a few very important differences:

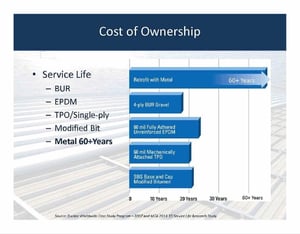

Service Life

This is important, an Independent Study conducted for the Metal Construction Assoc. (MCA) has shown that the expected service life of unpainted Zinc Aluminum coated, standing seam, roofs (Galvalume or equal) have a projected minimum service life of 60 years and a second study by the National Coil Coaters Association (NCCA) showed a projected minimum service life of 40 years for a painted PVDF roof. The expected service life for mechanically attached TPO is 18-24 years.

This means that your metal-over-metal roof proposal will have almost 3 times the life of the nearest competitor for a 20%-25% greater investment.

Wind Load

Promoters of TPO love to tout that they can meet the new higher wind loads. The reality is, yes, certain specific assemblies can meet the wind uplift requirements of the building code. That said many assemblies being proposed by contractors are designed on the basis of attaching to the existing “roof deck”. Metal building roofs cannot be considered as decking. Decking is 22 gauge, structural, heavily corrugated, metal panels. Structural metal building roof panels are typically 26 or 24 gauge, mildly corrugated panels with completely different structural properties than structural steel decking – Totally Different!

A properly attached TPO system must be attached to the structural purlins of the building. Most metal buildings have 5’ o.c. purlin spacings but many TPO systems attach their material 10’ o.c. skipping one purlin line! Good engineering practice never allows the skipping of any structural elements in a building, especially a purlin line. Be sure to find out what assembly they are proposing to use, look it up and read about its limitations. An easy place to do this is on the Florida Product Approval website where all the various assemblies are listed along with their attachment requirements, capacities and limitation of use.

A properly attached TPO system must be attached to the structural purlins of the building. Most metal buildings have 5’ o.c. purlin spacings but many TPO systems attach their material 10’ o.c. skipping one purlin line! Good engineering practice never allows the skipping of any structural elements in a building, especially a purlin line. Be sure to find out what assembly they are proposing to use, look it up and read about its limitations. An easy place to do this is on the Florida Product Approval website where all the various assemblies are listed along with their attachment requirements, capacities and limitation of use.

Snow Load

Snow Load

If you are in a snow load area, TPO’s can have a rough time here. The new building codes frequently have increased the ground snow load minimums and the now require the building be checked for “drift loading” or “Unbalanced loading” caused by the wind stacking snow on the roof in an uneven fashion. The major components of TPO systems are foam insulation and a 40-60 mil thick sheet membrane. None of these components are structural members and they rely on the existing, often deteriorated, old metal roof to support them.

Often when an analysis of the old metal roof is done it is found that the old metal roof cannot meet the current snow load requirements on the existing purlin spacing. This means that for the old roof to meet the building code, framing must be added to reduce the purlin spacing, not easily done beneath the existing roof. Therefore, this code requirement is frequently ignored by the single-ply contractors, Not Roof Hugger.

Roof Geometry

There is one constant when it comes to metal building design. Metal Roofs are never designed to have water standing on them. Metal building purlins are thin light weight Zee’s and are allowed to be designed with much more deflection than the typical conventional roof constructed with heavy bar joist and metal decking. Metal Buildings can do this because metal roof panels have ribs spaced from 12” -24” that channel the water from the ridge to the eave quickly and evenly; the water does not stand on the roof.

Too often metal buildings modified by single-ply contractors have filled parapet gutters with foam to fix a gutter problem and then installed scuppers through the parapet to let the water run out. The problem with this is that water must build up behind the parapet and then flow to the scuppers, stacking water on a roof that was never designed for this. The result can be catastrophic as happened in the photo above.

Other Considerations

Other Considerations

There are many other considerations to be reviewed when comparing a Metal roof retrofit to a TPO retrofit. They include:

Aesthetics: What will the building look like after retrofitted?

Fire: Metal roofing is considered non-combustible. What is the fire rating of the new roof going to be after a TPO system is installed?

Insurance: Will the insurability of the building be affected?

Solar: Metal roofing is hands down the best platform for the addition of photovoltaics. The new metal roof will last longer than the solar panels, eliminating the cost of the solar panel removal when the TPO roof has reached the end of its life. The solar panels can also be attached to the new standing seam roof panels without penetrating them.

Insulation: TPO contractors will point out the increase in energy efficiency their roof will provide. Metal roofing can also provide the same energy efficiencies plus we can provide what is called Above Sheeting Ventilation (ASV), which will ventilate the new air space between the old and new roofs reducing heat gain/loss in the summer and heat in the winter.

Strength: Retrofitting with Roof Hugger can actually add strength to the existing purlins overcoming the additional weight of the retrofit system. Members used to strengthen the roof for added snow loads are on top of the roof not inside the building making installation fast and easy. TPO systems just add weight.

Recap: A new metal roof may be a bit more expensive, but it is the best, longest lasting product in the marketplace today. It can meet all the new wind, snow and insulation requirements, yes, the best costs a little bit more but it is well worth it.

This is a guest post from Dale Nelson, President of Roof Hugger.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.