Metal roofs offer minimal maintenance, durability, energy efficiency, and a lifespan that can outpace shingled roofs by 40 to 50 years. Once you have decided to use metal products, it's time to dig into the specifics that ultimately drive product selection.  Whether you are working on a new construction build, replacing a worn-out shingled roof, giving an old metal roof a facelift, or retrofitting a flat metal roof to function better, McElroy Metal offers specific systems and knowledge to make the process as streamlined and hassle-free as possible. Bottom line: Whether your project is a new construction or a roof replacement, we're here to help!

Whether you are working on a new construction build, replacing a worn-out shingled roof, giving an old metal roof a facelift, or retrofitting a flat metal roof to function better, McElroy Metal offers specific systems and knowledge to make the process as streamlined and hassle-free as possible. Bottom line: Whether your project is a new construction or a roof replacement, we're here to help!

It's simple to add a metal roof to your project: consider your project specifics, desired aesthetics, substrate, color, and panel options to select the best product for your project!

Roof Specifics

The first considerations for any metal roof project involve the roof shape, slope, panel length, and building structure. Each of these criteria carries potential impacts on product selection. For example, many panel profiles are installed in a consistent left-to-right fashion. In contrast, others can be installed in any order, allowing sections to be skipped and addressed later. The installation sequence may be irrelevant for a project with a simple gable; however, a project with multiple hips, valleys, and dormers could benefit significantly from a panel profile that allows more flexibility during installation.

Roof slope is also an essential element. Low-sloped roofs (think 2:12 and below) typically can't be seen from the ground, moving panel style and aesthetics to a lower importance than cost and performance. In contrast, with a steep slope application (3:12 or greater), it's critical to consider all four criteria.

While most relevant for commercial applications, panel length can also be a determining factor. Between facility and transportation constraints, manufacturers often limit factory-produced panels to 50-60' in length. Consequently, large buildings often require the lapping of multiple panels to cover the entire span from ridge to eave. Each lap represents the purchase of additional components, installation time, and, perhaps most importantly, a potential leak as the roof ages.

When dealing with buildings of a large size and scope, it's often prudent to work with a manufacturer capable of producing single-piece panels up to 250' long at the roof's eave. This option reduces freight, lead and install time, and even dunnage since less panel packaging is required.

The building structure is another design consideration that affects your panel selection. Some panels require a solid substructure, such as plywood. While others can span open framing up to 5'. Using a structural panel with spanning abilities on a solid deck project often introduces unnecessary costs and, in some cases, even installation challenges.

Aesthetics

After factoring in building specifics such as shape, size, and complexity, most designers focus on aesthetic elements when considering roof design.

Color is the first obvious aesthetic. Choosing the roof color gives a project the finishing touch. The perfect color creates a visual cohesion that defines the style and impact of a building's appearance. Color options range from solids to metallics, with wood grain looks and specialty prints making an impact of late.

The wide variety of color options for metal roofing allows designers complete control. Do you want the roof to be a statement? Select a vibrant color or even a special finish color that matches your customers' branding. If another element takes center stage in your design, perhaps a more subtle roof color fits your project!

Beyond color, metal panels allow designers to introduce and control shadow lines. Selecting a rounded panel shape with a short ¾" tall rib introduces little, if any, movement or shadows. In contrast, choosing a vertical rib panel with a 2" tall leg, like our 238T, can offer substantial movement and architectural interest.

When selecting standing seam panels, the panel width is also a dominating factor in the overall appearance. A good rule of thumb is considering the panel width proportionately to the roof area. For example, a small roof area of 40' from gable to gable might look best with a 12" wide panel to maintain perspective. In contrast, a 12" wide panel might look incredibly busy on a roof that is 200' from gable to gable.

During the design phase, It's also important to consider if metal wall panels have a place in your project. Given their low maintenance, quick installation, and long life expectancy, metal wall panels continue to grow in popularity. If you're thinking of incorporating wall panels, take some time now to consider if you want to use the same panel for the roof and wall or if you're instead looking to create a complimentary feature. Some panels can be installed horizontally, while others cannot. Further, some wall panel configurations aren't appropriate for roofing applications. If you're interested in combining metal roof and wall panels, it may save you some time to contact us, and we'll help you save time by pointing you to the best options for your project.

You can also use our visualizer tool to see your project come to life with various color and panel options.

Substrates & Coatings

While color is one of the fun elements in roof design, material substrates and coatings deserve equal, if not greater, attention.

The substrate, or material used as the basis of the roof, is essential to the life expectancy and long-term aesthetic performance of any roof. Steel is an alloy made primarily from iron and carbon and is known for its strength, durability, and adaptability.

The most popular steel substrates in the metal roofing and siding industry are Galvanized and Galvalume®. Galvanized substrates are coated with a zinc alloy, while Galvalume substrates are coated with an alloy of zinc plus aluminum.

Galvalume and Galvanized are suitable substrates for metal panels; however, it's essential to realize that Galvalume substrates offer a 45-year warranty on the base metal. In contrast, no warranty is offered on a Galvanized substrate.

Although significantly more expensive, aluminum is another substrate option. Aluminum has been a long-favored product in coastal applications, given its propensity to resist salt spray. However, it is much lighter and, as a result, can't offer load-carrying and pull-out capabilities similar to steel roofing. It's also prone to much more significant expansion and contraction. Consequently, longer panel runs can be problematic.

Copper and stainless steel represent other substrate options for metal roofing, although due to cost and availability, galvanized and Galvalume steel represent the most common substrates.

With the substrate determined, it's time to consider coating systems. Painted metal roofing panels are typically coated with a high-performance system, and the most popular coatings for metal panels are PVDF (Kynar 500®), silicone-modified polyester (SMP), and polyester. Of the three, our Kynar 500® coatings provide the best protection against fade and chalk and are proven to deliver the best long-term performance. Recognized for their ability to provide long-term protection and durability, PVDF resin-based coatings offer building owners beautiful roofs that retain curb appeal year after year.

To create our stunning selection of colors, McElroy Metal partners with Sherwin Williams® Coil Coatings.

Product Selection

Once you've identified the criteria above, it's time to move to product selection. While there are some outliers, you'll typically find three different categories of metal panels: exposed fastened, concealed fastened, and specialty panels.

Once you've identified the criteria above, it's time to move to product selection. While there are some outliers, you'll typically find three different categories of metal panels: exposed fastened, concealed fastened, and specialty panels.

As the name implies, exposed fastener systems feature a visible fastener that attaches the metal panel to the substructure. Concealed fastened systems use clips or a pre-punched flange to connect the panel without visible fasteners. The category of specialty panels typically includes metal panels with a shingle-like appearance. For more information on the benefits of different panel styles, read this.

Exposed Fastener Systems

Exposed fastener panels offer impressive versatility thanks to the wide range of styles available - at McElroy Metal, customers can choose from twelve distinct panel styles. This family of panels typically boasts a wide cover width of 32-36" for each panel. That width means a quicker process for manufacturers and installers, contributing significantly to the fact that they tend to be the lowest price point.

These panels usually contain a pattern of repeatable ribs called major and minor ribs. The pattern, shape, and height of the rib impact the physical appearance; however, they also impact installation concerns, such as the recommended slope for the panel and whether a solid substrate is required under the panel.

- Max-Rib

- Multi-Rib

- R-Panel

- Mega-Rib

- Modern Rib

- Multi-Cor & M-Cor

- Mesa

- 5V

- U-Panel

Concealed Fastener Systems

Concealed fastener panels offer a unique aesthetic and architectural interest, giving a clean visual appearance perfect for modern designs. The concealed fasteners ensure a low risk of leakage thanks to the inherent design and flexibility of the panels.

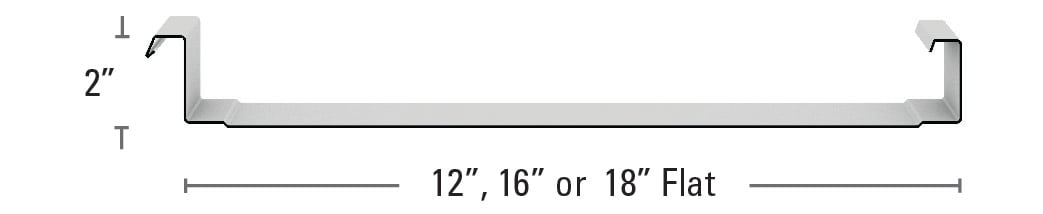

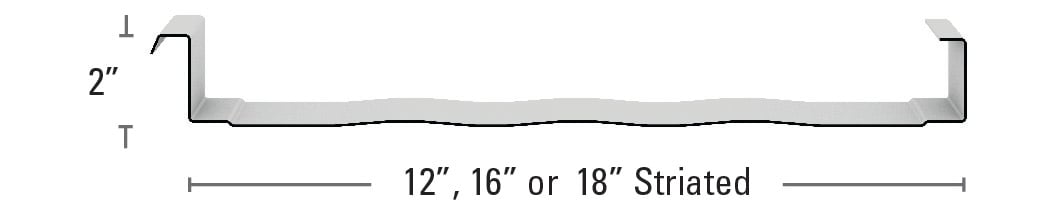

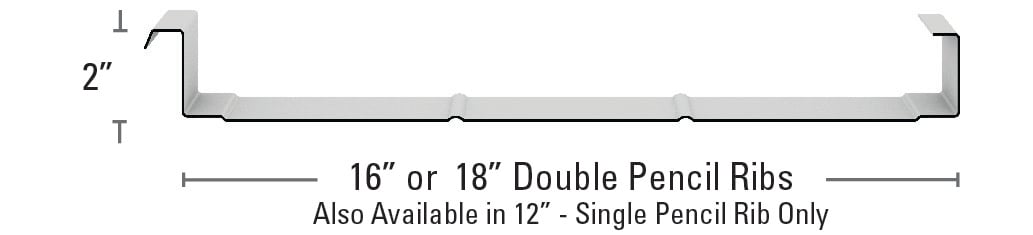

Panel widths for concealed fastened panels tend to fall in the 12" -24" range. As panel width increases, the cost per foot typically decreases; however, the opportunity for oil canning increases proportionately. For low-sloped applications where the roof isn't visible, a 24" wide panel can be a great solution; however, on steeper sloped roofs with high visibility, a narrower panel width tends to offer a more desirable aesthetic.

You'll also want to consider pan options when using a concealed fastener system.

Panel striations can be a highly effective approach to minimizing oil canning concerns. Consequently, we always recommend striations for a pan condition; however, we also offer other options for many of our panels, as shown below.

- Meridian

- Medallion-Lok

- Instaloc

- Medallion I

- Medallion II

- 138T

- 238T

Specialty Panel Systems

Specialty roofing panels represent an excellent solution for someone looking for a classic design style with all the advantages and benefits of metal materials. Designed to mimic the look of shingles or ceramic tiles, these beautifully designed panels will offer the durability contractors expect from their products.

- Met-Tile - Metal Roof Tiles

- Milan (Steel Shingles)

- Tilcor Stone Coated Roofing

If the various product options feel overwhelming, we're here to help! Visit our photo gallery and use the selector fields on the left to see real-life applications of our many different product styles.

Summary

While there is much to consider when designing a metal roof, don't be overwhelmed. Much like any other project element, it's important to find partners you trust and build relationships that help you deliver the best final project to your building owners. If we can help, don't hesitate to contact us. We're here to help.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=767&name=Understanding%20Load%20Tables%20(1).png)

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.