How Roof Pitch Affects Your Standing Seam Panel Selection

Between the dizzying array of panel styles and multiple manufacturers who all name their products something different, selecting the right product for a standing seam metal roof project can be as overwhelming as picking out the right club for a novice golfer.

But in most cases, answering one key question can significantly increase the odds of success.

What is your roof slope? Answering this question helps because standing seam metal roofing systems are really divided into two different groups. Those that are intended for low slope (think less than 3:12) and those that are designed for steep slope applications, or those 3:12 and above.

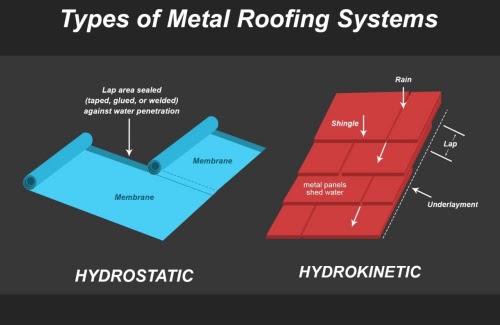

Lower slope roof systems often require a hydrostatic roof system in order to keep the building watertight. By definition, a hydrostatic system means that water can be “static” or not moving and the system can still function. This is important because in times of intense rainfall, water doesn’t always drain from low sloped roofs immediately. Consequently, many hydrostatic roofing systems are also mechanically seamed systems

Roofs 3:12 and above often use a hydrokinetic standing seam roof system. Meaning that water needs to be “moving” over the panels in order for them keep the building watertight.These systems typically don’t require the use of a seaming machine and instead may be snapped together during the installation process.

Image source Kravelv.com - https://www.kravelv.com/metal-roofs-vs-hurricanes/

The substrate that the metal roofing panels attach to is also related to the roof slope. Low slope buildings are often designed where panels will span purlins instead of attaching to a solid deck. Since secondary water barrier products like ice and water shields can’t be installed over open framing, the systems are designed to be watertight on their own or hydrostatic. Pre-engineered buildings are a great example of this construction method.

Conversely steeper slope roof assemblies generally involve panels attaching to products like rigid insulation or a nailbase type product and these systems, while typically less expensive to install, do require secondary water barrier products like ice and water shield to keep the building envelope water tight since they are hydrokinetic.

In closing, it’s important to note that panels intended for low slope applications can be installed on steep slope roofs but those intended for steep slope are usually not appropriate for low slope roofs.So back to our golf analogy, you can always club up but you want to club down on standing seam roof systems with extreme caution and only after talking to the manufacturer about your project specifics.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.