8 Things to Consider When Selecting the Gauge for Metal Roof and Wall Panels

One of the more common questions we receive involves selecting the proper gauge for metal roofing and siding panels. We’ve been helping contractors, architects, and homeowners work through the pros and cons of decisions like this for the last 59+ years, so we’re happy to help.

What is Gauge?

Gauge refers to the thickness of metal roofing and siding panels. Standard gauges for metal products include 29 gauge, 26 gauge, 24 gauge, and 22 gauge, with the smaller number representing the heavier (or stronger) gauge.

Each gauge referenced above includes a range of nominal decimal thicknesses. Consequently, two metal panels can be the same gauge yet be slightly lighter or heavier than each other.

Things to Consider in Gauge Selection

Appearance. Metal panels are prone to oil canning. While there are no guarantees, heavier panel gauges can help reduce the appearance of oil canning. So if you’re dealing with a high-profile project or darker colored roof panels, it’s important to understand that moving to a heavier gauge panel may be worth the additional cost. If you’re not familiar with oil canning, learn more about it (and tips to avoid it) here.

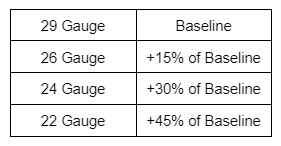

Appearance. Metal panels are prone to oil canning. While there are no guarantees, heavier panel gauges can help reduce the appearance of oil canning. So if you’re dealing with a high-profile project or darker colored roof panels, it’s important to understand that moving to a heavier gauge panel may be worth the additional cost. If you’re not familiar with oil canning, learn more about it (and tips to avoid it) here.  Cost. Cost is a common factor when selecting metal roofing and siding products. While heavier gauge panels certainly offer benefits, they also cost more. You can expect approximately a 15% cost difference between each gauge as a rule of thumb. While you can see an example in the table to the right, it’s always best to contact us to discuss your specific project.

Cost. Cost is a common factor when selecting metal roofing and siding products. While heavier gauge panels certainly offer benefits, they also cost more. You can expect approximately a 15% cost difference between each gauge as a rule of thumb. While you can see an example in the table to the right, it’s always best to contact us to discuss your specific project.- Load considerations. It is essential to consider loads when selecting the gauge of metal panels. Most manufacturers, including McElroy Metal, routinely publish load tables for each product on their websites. It’s vital to check these published load tables against the building documents to ensure your selected gauge offers the required performance. While it should never be assumed, heavier gauges of the same panel profile typically offer higher load capacities.

- Dead Load. While metal roofing and siding panels weigh far less than most other material options, the panel weight is still important in dead load calculations. As the panel gauge increases, the weight of the panel (or applied dead load) also increases. While typically not an issue with new construction, some renovation projects can struggle to support the additional dead load of heavier gauge panels.

Testing requirements. Most reputable panel manufacturers conduct testing on their panels to meet various performance standards. The gauge of metal panels is directly related to the testing results and the type of performance you can anticipate. For example, heavier gauge panels tend to offer higher wind uplift values. To learn more about metal panel testing, check this out.

Testing requirements. Most reputable panel manufacturers conduct testing on their panels to meet various performance standards. The gauge of metal panels is directly related to the testing results and the type of performance you can anticipate. For example, heavier gauge panels tend to offer higher wind uplift values. To learn more about metal panel testing, check this out. - Roof structure. Some metal panels can span between open supports, while others require a solid substructure like plywood or metal decking. Consequently, the roof structure is always an important consideration when selecting a panel gauge. For example, post-frame projects routinely use the lighter 29 gauge material to span wooden purlins @ 2’ on-center. In contrast, 26 or 24 gauge material is customary for the 4-5’ purlin spacing you find with pre-engineered buildings.

- Inventory. To minimize inventory, metal panel manufacturers inventory specific gauges for each panel profile. Requesting panel gauges outside the manufacturer's standard offering can push the material into a special order situation that often increases cost and lead time. To view our standard offering, check out our panel selector tool.

- Environment. Heavier gauges typically perform better in harsh environments, so projects located in areas prone to extreme weather events like high wind speeds and hail typically benefit from heavier gauge panels.

Still unsure of what panel gauge is best for your project? Contact us; we’re happy to help you navigate this topic!

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.