Metal Roofing Substrates and Coatings Explained

Gone are the days of limited options for metal roofing. Today’s metal roof buyers can choose from an exciting array of both colors and styles. And there's certainly no doubt that like many other purchases, aesthetics are an essential part of the selection process with metal roofing.

However, it's also important for buyers to consider the quality of the metal substrates and coatings for those situations when life expectancy and long-term performance are important.

Picking the right substrate and coating combination will determine the quality of your roofing project, the long-term beauty of your metal roof, and ultimately the return on your investment.

Let's dig into some key features that will help you make the right decision.

Metal Roofing Substrates

Underneath the paint/coating, the substrate of the actual metal is the heart of a metal roof panel.

There are two common steel substrates available today, Galvanized and Galvalume®. Galvanized substrates feature a zinc coating applied to the raw steel while Galvalume substrates feature an alloy of zinc plus aluminum.

Both of these substrates are of good quality. However, Galvalume substrates offer homeowners the highest quality long-term solution. Let’s take a closer look at the two substrates.

If a homeowner is considering Galvanized substrates, it is important to know there are different levels of quality. For example, two common galvanized substrates are known as G100 and G60. The numerical designation refers to the amount of zinc contained on both sides of the panel surface. That is an important difference because when it comes to performance, the higher the amount of zinc, the more resistant the panel will be against corrosion.

With 66% more zinc than G60 substrates, G100 substrates will last far longer than their G60 counterparts. The performance difference is significant enough to state that G60 substrates are not considered appropriate for residential roofing.

That being said, G60 substrates are widely available in the marketplace, so homeowners must understand the difference in performance and ask their contractor or distributor questions about the substrate they typically install.

That being said, G60 substrates are widely available in the marketplace, so homeowners must understand the difference in performance and ask their contractor or distributor questions about the substrate they typically install.

The addition of the aluminum alloy enables Galvalume substrates to outperform galvanized for the long-term. At McElroy Metal, we generally recommend homeowners opt for a Galvalume substrate over even a G100 substrate. (Based on performance limitations, we don't even offer a G60 for residential applications).

Our recommendation is based on decades of research and actual field performance. Galvalume delivers better results, excellent corrosion resistance, and long-term aesthetics. Galvalume substrates also carry a warranty from Steel Mills against rupture or perforation due to corrosion. Similar Steel Mill warranties for Galvanized substrates simply don’t exist.

Metal Roofing Coatings

Polyester systems are the least expensive option but are also the lowest-performing. With the greatest potential for chalk and fade, polyester systems have the shortest lifespan and are not typically recommended for residential roofing.

Polyester systems are the least expensive option but are also the lowest-performing. With the greatest potential for chalk and fade, polyester systems have the shortest lifespan and are not typically recommended for residential roofing.

Silicone-Modified Polyester (SMP) is a better performing option than polyester systems. The SMP paint systems will still experience fade and chalk, but not to the same degree as polyester coatings.

PVDF (Kynar 500®) paint systems are the best performing option available to homeowners. In terms of service life, color retention, and chalk-resistance, PVDF systems simply can’t be beaten. PVDF (Kynar 500) paint systems are superior and will offer a like-new appearance year-after-year.

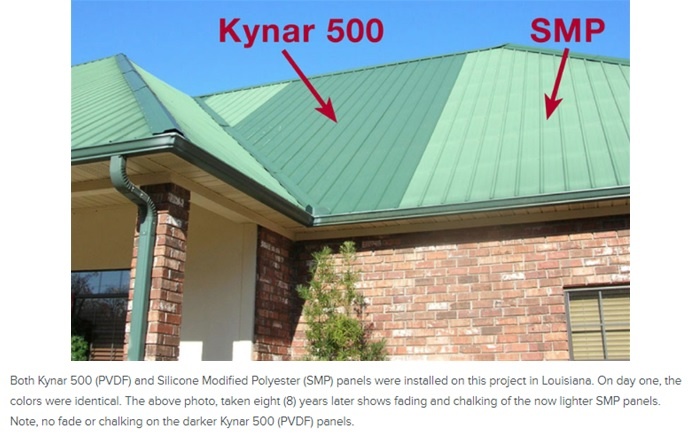

It is perhaps easiest to "see" the difference in quality with Kynar 500 paint systems. The image below shows a home that had the exact same color SMP and Kynar 500 coated panels installed. Eight years after installation, the image below was taken.

Notice the stark contrast in performance between the two systems. The Kynar 500 roof still looks new while the SMP roof has experienced significant fade and chalk.

GALVALUME® is an internationally recognized trademark of BIEC International Inc., and some of its licensed producers.

Kynar 500® is a registered trademark of Arkema Inc.

Learn More

Want to learn more about selecting a metal roofing system for your home?

The Residential Metal Roofing Guide explains the most common types of residential roofing substrates, coatings, warranties, and panel options.

Click the button below to download your copy!

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.