It's no secret that metal roof systems are superior to traditional asphalt shingles. Besides their recyclability and lighter weight, longevity, and aesthetics are two of the most popular reasons consumers choose a metal roof system for their home.

However, not all metal panels are created equal. Like most other building materials, metal roofing panels vary in quality and performance, depending mostly on the metal substrates and coatings.

Let’s explore these critical components that affect the performance, longevity, and appearance of your new metal roof.

Metal Roofing Panel Materials

In metal roof panels, the steel substrate refers to the base metal material with a corrosion-resistant metallic coating. The two types of coating are Galvanized and Galvalume®.

Galvanized Substrates

Galvanizing is the process of coating metals with corrosion-resistant materials. This involves applying a zinc coating over raw steel. The coating’s thickness is subsequently measured by a G-rating scale from 60 to 100+.

The G-rating number refers to the amount of zinc on the surface of the steel sheet. More zinc means better corrosion protection and a longer service life.

- G60 substrates contain 60 ounces of zinc per 100 square feet of metal panel.

- G100 substrates contain 100 ounces of zinc per 100 square feet, offering 66% more protection than G60

McElroy Metal no longer offers G60 panels due to their shorter lifespan. We recommend G100 as the minimum for your exterior projects.

Galvalume Substrates

Galvalume is an alloy of zinc and aluminum. This corrosion-resistant metallic coating can extend the lifespan of your metal roof to 50 years and beyond, needing minimal repair or maintenance.

Galvalume substrates offer the best long-term solution for most applications. Decades of testing have shown its superior corrosion resistance compared to Galvanized panels.

Due to its performance, steel mills offer warranties against rupture or perforation due to corrosion for Galvalume — steel mill issued warranties are not offered for Galvanized panels.

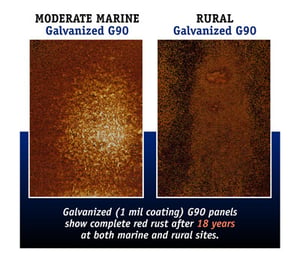

In one test, unpainted Galvalume and Galvanized panels were placed in four outdoor environments, including marine and rural settings. The harsher the environment, the better Galvalume performed. After 23 years of side-by-side comparison in all areas, Galvalume proved two to four times more durable than Galvanized.

Download Our Galvalume Brochure to Find Out More

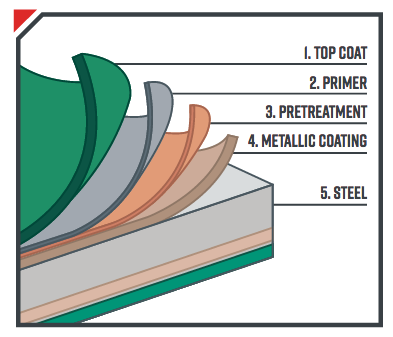

Coating Types for Metal Roofing Panels

Due to its constant exposure to the weather and UV rays, selecting the proper coating is just as important as the substrate. There are three popular coating options:

1. Polyester Paint

Polyester is the cheapest paint option, providing the least protection against chalking and fading. It looks great when first installed but begins to fade and chalk soon after.

Due to its short lifespan, polyester paint should be limited to interior use or basic shade and shelter projects where long-term performance is not required.

2. Silicone Modified Polyester Paint (SMP)

SMP, or silicone-modified polyester paint, outperforms simple polyester due to its 30% silicone content. The added silicone enhances fade and chalk resistance, improving performance compared to straight polyester coatings.

However, SMP’s hardness can cause micro-fractures during the manufacturing process. These fractures expose the material to the elements, which can initiate corrosion. At McElroy Metal, we use thermoforming technology to reduce this risk for our Max-Rib panel with SMP coatings.

3. Fluoropolymer/PVDF (Kynar 500®)

Kynar 500 resin in fluoropolymer/PVDF coating provides superior protection against chalking and fading. To be classified as Kynar 500, the polyvinylidene fluoride (PVDF) component must make up 70% of the total resin content.

Kynar 500 has been used since the late 1950s. Originally developed for high-end projects, you can now find Kynar 500 paint systems in use on many pre-engineered buildings, post-frame buildings, and residential roofs nationwide.

Although Kynar 500 paint systems cost more than SMP, their enhanced performance justifies the expense. Indeed, the up-charge for Kynar 500 coatings is often insignificant compared to the overall cost of a building or metal roofing system.

Choosing the right substrate and coating will affect your roof's lifespan and appearance. Understanding all the options available allows you to make the best choice for protecting your home and your investment in a metal roof.

Learn More About Why You Should Choose Kynar 500® for Your Metal Roof

Comparing Metal Roofing Types: Standing Seam vs. Exposed Fastened Panels

Metal roofing panels vary in shape and profile. The two fundamental types are standing seam and exposed fastened panels.

Standing Seam

These roofs feature raised seams running vertically from the ridge to the eaves. Thanks to the lack of visible fasteners used during installation, they offer a sleek, modern appearance and superior weather resistance. Standing seam panels are ideal for residential and commercial buildings requiring durability and low maintenance.

Exposed Fastened Panels

Exposed fastened panels install with a gasketed screw. This panel style consists of a series of major and minor ribs and can range from old style corrugated products to industrial and modern designs. While less expensive to initially purchase and install, this panel style may require more maintenance over time.

Considerations for Environmental Impact and Sustainability

Compared to most alternatives, metal roofing offers significant environmental benefits. These include high recyclability and energy efficiency.

Metal roofing panels are 100% recyclable at the end of their life, reducing landfill waste. The Environmental Protection Agency (EPA) estimates that 11 million tons of asphalt shingles end up in a landfill every year. Due to its recyclability, metal roofing is an attractive option for those looking to implement environmentally sustainable materials into their building projects.

Metal roofs reflect solar heat, reducing cooling costs. Additionally, their long lifespan minimizes the need for frequent replacements.

Metal roofs are also compatible with solar panel installations.

Cost Analysis: Investing in Longevity and Durability

The initial cost of metal roofing can be higher than that of traditional roofing materials. However, when considering long-term savings, metal roofing is an investment that pays dividends. Factors such as durability, energy efficiency, and maintenance costs all contribute to its overall cost-effectiveness.

Standing Seam Metal Roofing typically carries a higher upfront cost due to the complexity of the installation, additional packaging and manufacturing differences. However, the extended lifespan and minimal maintenance requirements can lead to significant savings over time.

Exposed fastener metal panels offer a more budget-friendly option without sacrificing performance. While the initial savings are appealing, it’s important to consider the potential for slightly higher maintenance costs and the shorter lifespan compared to standing seam systems. Regardless, exposed fastener metal panels offer a durable, energy-efficient roofing solution that can withstand the elements for decades.

Either way, metal panels deliver a stronger return on investment for homeowners than shingles.

Installation and Maintenance Tips

Proper installation is crucial for maximizing the lifespan of your metal roof. Follow these tips for proper installation and maintenance:

- Ensure all fasteners are correctly tightened and seams are sealed to prevent leaks.

- Avoid walking directly on the panels to prevent damage.

- Perform regular maintenance: inspect for loose fasteners, clean debris from the roof surface, and check for any signs of wear or corrosion.

By following these tips, homeowners and contractors can ensure a long-lasting, visually appealing metal roof with minimal maintenance needs.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.