So, do steel roofs rust? The short and sweet answer is yes. Steel rusts, especially when exposed to weather conditions over a long period.

The question metal roofing buyers should ask instead is - how to reduce the risk or minimize the potential for rust. The answer is simple: become an educated consumer and put an emphasis on choosing the right metal substrate before starting any metal roof project.

In this blog, we will be covering:

- Rust vs. Corrosion

- Comparison of Metal Roofing Materials and Choosing the Right Substrate

- Role of Protective Coatings and Which Coating Systems are Best?

- Proper Installation

Rust vs. Corrosion

Rust is a common term used to describe the process of corrosion. Rust specifically refers to the reddish-brown flaky compound called iron oxide, which forms on iron and iron alloys when exposed to moisture and oxygen. This process weakens the metal making it brittle. Corrosion is a broader term that describes the natural aging and change in the appearance of metals due to chemical reactions with the environment. Cut edge corrosion occurs when metal panels come in contact with oxygen and moisture. At McElroy Metal, we apply a clear coat rust inhibitor at the ends of our Max-Rib and Mesa panels to minimize corrosion.

Comparison of Metal Roofing Materials and Choosing the Right Substrate

It's not unusual for homeowners to spend more time picking out the color for a new metal roof than they spend thinking about the substrate of the steel. And admittedly, it isn't nearly as much fun! But the reality is that the substrate is essential to the life expectancy and long-term aesthetic performance of any roof. Therefore, homeowners focusing more on color than substrate choices often face premature rusting and find themselves stuck with a roof that needs replacement much quicker than expected.

Steel is an alloy made primarily from iron and carbon. It is known for its strength, durability, and adaptability. To protect against rust, many steel roofs are coated with zinc (galvanized) or a combination of zinc, aluminum, and silicon (Galvalume®). These coatings create a barrier that prevents the underlying steel from rusting.

Galvanized substrates are coated with zinc alloy to protect against corrosion. The effectiveness of the coating depends on the amount of zinc. Generally, panels with a higher percentage of zinc provide enhanced protection. Two commonly used Galvanized substrates are designated as G100 and G60. These designations relate to the total amount of zinc on both sides of the panel surfaces. G100 contains 1.0 ounce of zinc for every square foot of panel, while G60 substrates contain 0.6 ounces of zinc. It's important to realize that a G100 substrate contains 66% more protective zinc than a G60 substrate. This difference directly impacts how long the roof will last. As a result, G60 substrates simply do not provide the longevity and performance expected by most homeowners. Yet, G60 substrates are widely available. For the uneducated consumer, it’s an easy mistake to make and one that likely leads to a metal roof with accelerated rusting and failure.

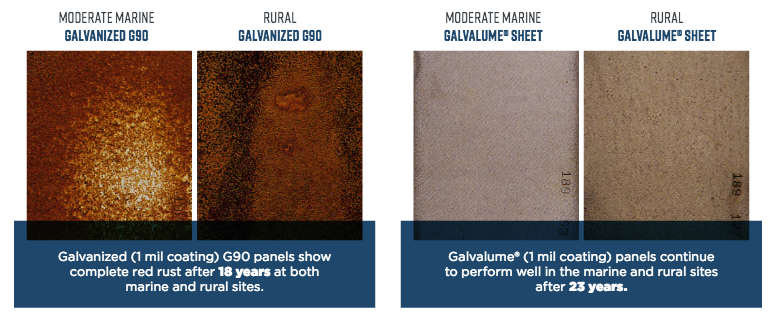

Galvalume® substrates offer excellent rust protection by combining zinc and aluminum coatings. Most manufacturers recommend Galvalume® substrates for residential roofing applications due to their field performance over many decades. Over four-plus decades of testing and field performance have shown that Galvalume® delivers greater corrosion resistance than galvanized panels. The performance of Galvalume® in the construction industry has been so superior that steel mills warranty it against rupture or perforation due to corrosion. Similar steel mill warranties simply do not exist for galvanized substrates, regardless of the amount of zinc.

Aluminum roofs naturally resist rust because they create a protective barrier called an aluminum oxide layer when exposed to moisture. Aluminum is softer than steel, can be more costly, and damage could occur in areas prone to strong wind, hail, or other environmental pressures.

Copper roofs possess inherent rust resistance because of their unique corrosion properties. When copper is exposed to air, it reacts with oxygen to create a layer of copper oxide. This layer gradually converts into copper carbonate, which gives copper structures the recognizable green patina. Although copper roofs don’t rust like iron or steel, they undergo a corrosion process, forming a protective layer.

Zinc roofs indeed have the advantage of developing a protective layer, just like copper roofs. However, the patina on zinc is unique because it has the ability to self-heal. If the surface gets scratched or damaged, the patina can repair itself and act as a barrier against further corrosion. This makes zinc an attractive option for those looking for a durable roofing material.

Role of Protective Coatings

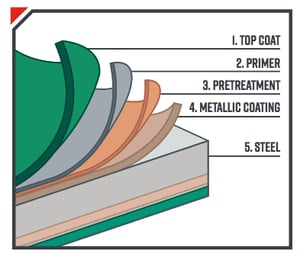

Protective coatings play a crucial role in enhancing the durability and performance of metal roof and wall panels. Coatings act as a shield, creating a barrier between the metal and the external environment. Not only do protective coatings prevent rust and corrosion, but they can also enhance the aesthetics of metal roofs and wall panels.

Protective coatings play a crucial role in enhancing the durability and performance of metal roof and wall panels. Coatings act as a shield, creating a barrier between the metal and the external environment. Not only do protective coatings prevent rust and corrosion, but they can also enhance the aesthetics of metal roofs and wall panels.

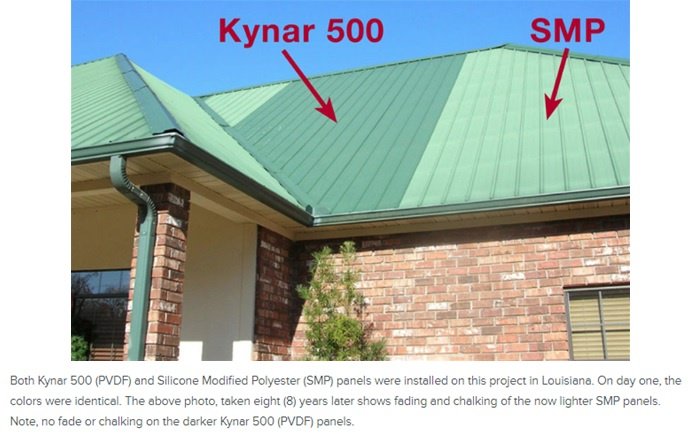

Polyvinylidene Fluoride, or PVDF (Kynar 500®), and Silicone Modified Polyester (SMP) are among the top choices for metal panel coatings. Among these options, Kynar 500® is well-known for exceptional defense against fading and chalk and a proven long-term performance. Whether you are a homeowner or a commercial building owner, PVDF-based coatings offer the advantage of having visually appealing and long-lasting roofs that retain their charm for many years.

Proper Installation

Here are some important points to keep in mind when installing a metal roof:

- Aim for clean and precise cuts to ensure a good fit when cutting the edges.

- Drive the fasteners correctly, and avoid overdriving, underdriving, or driving them in at the wrong angle. This ensures the stability of the panels and helps prevent rusting.

- Once the metal roof is installed, it is recommended to inspect it thoroughly at least once a year. During this inspection, check for any exposed edges, deep cuts, scratches, or other issues that could lead to rust. By addressing these issues promptly, you can maintain the longevity and durability of your roof.

Remember, proper panel installation and regular maintenance are key to ensuring your metal roof remains rust-free and in excellent condition.

Conclusion

Let's face it, the roof is a key element of every home in its appearance and function. The right combination of substrate and coating for metal roofing can give homeowners peace of mind for decades. But cutting corners on substrates and paint systems to save a little bit of money today, can also result in premature failure for the total roofing system. McElroy Metal’s paint supplier is Sherwin-Williams®. While McElroy Metal offers Polyester, Silicone-Modified Polyester, and Kynar 500®/PVDF coatings, based on performance, we strongly recommend PVDF coatings for residential applications where long-term aesthetics and performance are the top considerations for homeowners.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.