Coatings vs. Metal Roofing Costs

So your metal roof is leaking. We get it; whether the building houses your inventory, production operations, or even your personal stuff, there’s no bigger mess than water. Consequently, when faced with a leaking metal roof at the end of its first service life (usually 60+years), owners often gravitate to the quickest and cheapest solution, roof coatings, instead of replacing the metal roof.

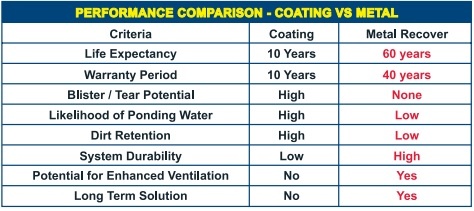

While fast and cheap can be undoubtedly attractive, there are many other considerations on something as important as your roof. The chart below lines up coatings and metal roof replacement against each other in eight additional categories.

After reviewing the chart above, you can see that the story is much more complex than the simple speed of installation and initial cost. Metal roofing far outshines coatings in each of the eight categories above.

Top Considerations

How long are you planning to keep the building?

Like any other capital investment, it’s essential to consider the complete picture before making any decision. And one of the first things to consider when comparing coating vs. replacement of a metal roof is how long you plan to keep the building. As the chart above illustrates, coatings have a 10-year life expectancy, where metal roofing has a 60-year life expectancy.

So if you plan to keep your building for more than 7-8 years and don’t want the hassle of water leaks and roof replacement again (and really who does?), it’s likely intelligent to fully explore replacing your metal roof with a new metal roof. Will you deal with leaks a little longer in the short term? Probably, but chances are you’ll only have the hassle for a few more weeks upfront and gain peace of mind for an extra 50 years on the backend when you go with a new metal roof instead of roof coatings. Not a bad trade-off in most owners' minds!

But even if peace of mind isn’t that important to you and you’re not planning to own the building past the 7-8 year mark, it’s important to realize that money spent on a metal roof carries a return on investment for you. Most buyers (and certainly their lenders!) frown on purchasing a building that needs a roof replacement in just a few short years.

Consequently, the chances are good that you’ll either need to lower your selling price or replace the roof as a condition of sale if you apply a coating over a worn-out roof and look to sell the building. If you’re paying for it anyway, doesn’t it make far more financial sense to pay for a long-lasting roof from the beginning so you can enjoy the tax advantages and peace of mind instead of doing all that for a new owner?

Coating vs. New Metal Roof Cost

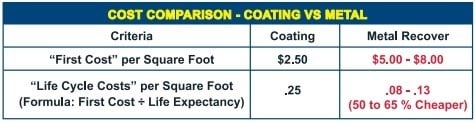

Cost is a factor in every building owner's decision. And rightfully so since there are unlimited demands on places where you can spend money. Ultimately though, like many other decisions, this one boils down to pay me now or pay me later.

Granted, installing a new metal roof will likely cost 2-3 times initially what it would cost to put a coating on the same roof; however, metal roofing will last 6 times longer. Consequently, it’s essential to consider the terms “first cost” and “life cycle costs.” First cost means just what you would expect; it’s the cost you paid for the product and installation on day one. Conversely, life cycle costs to factor in things like ongoing maintenance and life expectancy into the equation.

In the chart below, you can see that when you consider the roof’s life expectancy, the cost of installing a new metal roof is half the cost of applying a coating to the same roof. So while it might seem more expensive initially, metal roofing is much cheaper in the long run.

And as a bonus, you can scratch it off your list of things to worry about for several decades, if not the rest of your life. Eliminating future surprises and maintenance problems is a win in and of itself to most building owners.

Business Interruption/Soft Costs

While metal roofing wins the discussion of life cycle costs hands down, it’s vital to consider soft costs such as business interruption in the decision between roof coatings and metal roof replacement.

For a significant number of years, installing a new metal roof meant ripping off the old roof and replacing it with new panels. It doesn’t take much of an imagination to picture the chaos that a metal roof replacement once meant. Limited options often forced owners to relocate operations and inventory to other areas during tear-off and new panel installation. During this time, the ease of installation and lack of business interruption that coatings offered closed the gap on the reduced life expectancy for many building owners. But those tides are turning.

McElroy Metal, and a few other national manufacturers, now offer recover and retrofit systems installed over the existing metal panels. Not only do these systems allow for business as usual during the re-roofing, but they also make it easy to add extra insulation during the process. While the additional insulation certainly isn’t a requirement, many savvy business owners see added insulation as a great way to reduce future utility bills and take advantage of the opportunity to beef up their insulation during the recovery process. (This simply isn’t an option with roof coatings.)

System Durability

System durability is another significant consideration between roof coatings and metal roof replacement. We’ve already addressed that coatings have a life expectancy of 10 years while metal roofing routinely lasts 60 years, so you can clearly expect better performance from metal panels than roof coatings. But why?

First, as you might expect, metal panels are much more resilient than roof coatings. Let’s face it; many different elements attack roofs. A few of the common culprits include foot traffic on the roof for maintenance purposes, mother nature with extreme sunlight; temperatures; winds; and even hail in some parts of the country. Then throw in some unexpected things like overhead trees dropping branches or birds dropping, well, you know, and the picture becomes painfully clear. Your roof literally takes a beating, and its primary job is to protect you and your contents. There’s simply no denying that a solid metal panel offers better protection against the environment than a thin coating, and quite simply, it’s reflected in each product’s life expectancy.

Secondly, it’s important to understand that buildings constantly expand and contract with temperature changes throughout the day. Metal roof panel manufacturers have designed their standing seam roof systems with clips to accommodate this phenomenon called thermal cycling.

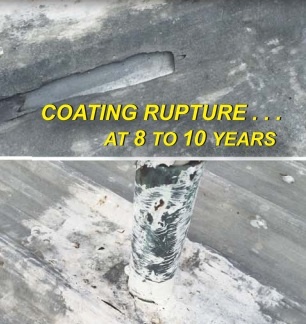

Based on their chemical composition, roof coatings simply can’t expand and contract to the same degree as metal roof panels. Consequently, since their ability to move is limited, they are subject to tears and blisters, and shown in the photos below.

The force that mother nature applies simply needs to go somewhere so the coating tears at the weakest or greatest point of impact. It’s important to remember that each tear represents a roofing failure and an opportunity for water to enter the building.

Summary

So how do coatings and metal roofing costs compare? If you’re looking for the lowest initial price and quick fix, coatings might be for you. If, however, you are looking for the most economical roof over the life of the building, see your building as an investment and value the durability of your roofing system, contact us.

We’d love to talk about your specific building and help you further explore the difference in costs and performance between coatings and metal roof replacement.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

.png?width=767&name=Understanding%20Load%20Tables%20(1).png)

.png?width=440&height=293&name=How%20to%20Install%20Metal%20Roofing%20Over%20Existing%20Metal%20Roofs%20(1).png)

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.