When it comes to metal roofing, performance and safety are at the top of every checklist. Selecting quality products, reviewing your options, and feeling confident in your choice can be overwhelming. Like many products, metal roofing undergoes rigorous testing during development to confirm that it meets a variety of important standards. Routine metal roofing product testing covers everything from structural integrity to the ability to resist fire and flame spread and so much in between.

Interpreting testing measures correctly is important, and it can be challenging to know how to use those insights when making your selection as a designer and a consumer.

What makes a product stand out from the crowd? Meet Class 4 materials. Class 4 is an impact test standard used for shingles and metal roofing, ensuring the highest performance and safety levels.

How Are Materials Tested for "Class 4 Status"?

Underwriters Laboratories (UL) is a not-for-profit independent testing organization that delivers verified information to help consumers make accurate product decisions.

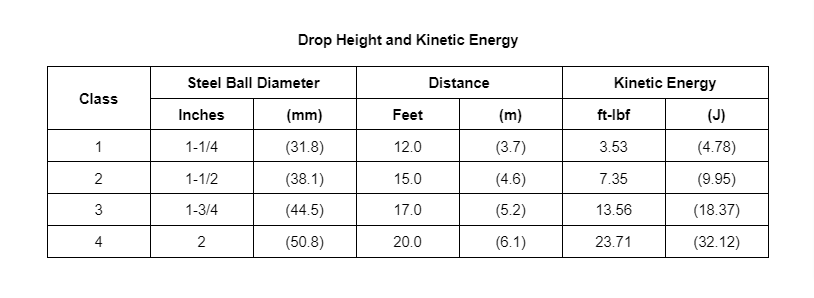

UL developed a test to rate the strength of roofing materials called the UL 2218 Impact Rating. These test results help determine if a roofing material is Class 1,2,3, or 4.

As the chart above depicts, UL 2218 testing is completed by dropping four different-sized metal balls from various heights to simulate hail. During the test procedure, the material must “show no tearing, fracturing, cracking, splitting, rupture, crazing or other evidence of opening”. If the test product tears or fractures, it is considered a failed test.

Shingles are rated Class 1 through 4, with Class 4 shingles having the highest impact resistance. Typically, you cannot tell the impact rating by looking at a shingle. The underside of the shingle or packaging usually shows the impact rating.

Impact resistance is important because it measures resistance to hail and debris, and while generally speaking, you can’t label something as “hail proof,” products classified as Class 4 meet the most substantial level of resistance that UL has deemed appropriate.

With Class 4-rated metal systems, your roof is far more likely to remain watertight even after storm damage. Therefore, purchasing products with a Class 4 rating means you will have a smaller likelihood of damage after a hail event or a storm where debris has made contact with your roof.

Replacing a roof is not the only expense when roofing fails – if the hail and debris cause a leak, additional damage is likely to occur inside the building.

Are All Shingles and Metal Roofs Class 4 Roofs?

No! The vast majority of shingle roofs haven’t been impact-tested. Interestingly, those with successful Class 4 testing run 10-20% more expensive than their non-testing counterparts.

In contrast, most metal roofs are impact-resistant and rated Class 4. In fact, McElroy Metal has over two dozen profiles in steel with a Class 4 rating available in thicknesses down to 29 gauge.

Based on years of data showing Class 4 roofing products lead to lower lifetime roofing costs and fewer replacements, many insurance companies offer reduced insurance premiums for those using Class Four products. If you are considering a roof replacement, talk to your insurance agent about premium discounts associated with investing in a Class 4 roof.

Depending on your region, different risks impact your decision about which material fits your project best. Let's examine a few possible risks and why Class 4 metal roofing is the right fit.

Risk #1: Hail

After extensive hail damage totaled his shingle roof, Ronnie McGlothlin, president and owner of Empire Roofing in Fort Worth, Texas, turned to the roof he knew he could trust to weather just about any storm, McElroy Metal's 138T system, a standing 1-3/8-inch high seam. “I like everything about this roofing panel,” Ronnie says. “What I like most is the ease of replacement if something happens to one or two panels. If a panel is damaged by weather or someone working on the roof, I can just replace the damaged panel or panels. I don’t have to tear off panels all the way to one end or the other.”

After extensive hail damage totaled his shingle roof, Ronnie McGlothlin, president and owner of Empire Roofing in Fort Worth, Texas, turned to the roof he knew he could trust to weather just about any storm, McElroy Metal's 138T system, a standing 1-3/8-inch high seam. “I like everything about this roofing panel,” Ronnie says. “What I like most is the ease of replacement if something happens to one or two panels. If a panel is damaged by weather or someone working on the roof, I can just replace the damaged panel or panels. I don’t have to tear off panels all the way to one end or the other.”

Safety, longevity, and ease of maintenance - it sounds like a metal roofing system was the perfect choice for Ronnie's dream home! Renee Ramsey, executive director of the Metal Roofing Alliance (MRA), agrees, "Metal roofs are by their very nature extremely strong and durable. For homeowners who need to replace their roofs due to hail damage, it’s a wise investment to go with a material that’ll better protect their home the next time a severe storm passes through.”

Risk #2: Hurricanes

While we can't guarantee that any roof is "hurricane proof", a properly designed and professionally installed metal roof can withstand the damage that outpaces what hurricane-prone areas typically experience. Metal roofing continues to garner more and more attention for its outstanding performance in post-hurricane analysis.

Proper product selection is critical in hurricane-prone areas; however, it’s also essential to properly vet and select the right partners. Engineers, manufacturers, and installers all represent crucial functions in your project, and it’s vital to do your due diligence before assembling your project team.

Risk #3: High Winds

When winds reach 140+ miles per hour, insufficient roofing can have devastating effects. From ripping away unstable pieces to creating dangerous projectiles, wind damage can be treacherous.

McElroy Metal has crafted metal roofing systems that negate the issues often found in high-wind areas. Innovations like the 138T Shingle Recover System offer unmatched wind uplift resistance and improved weathertightness.

How Do I Know If I Have An Impact-Resistant Roof?

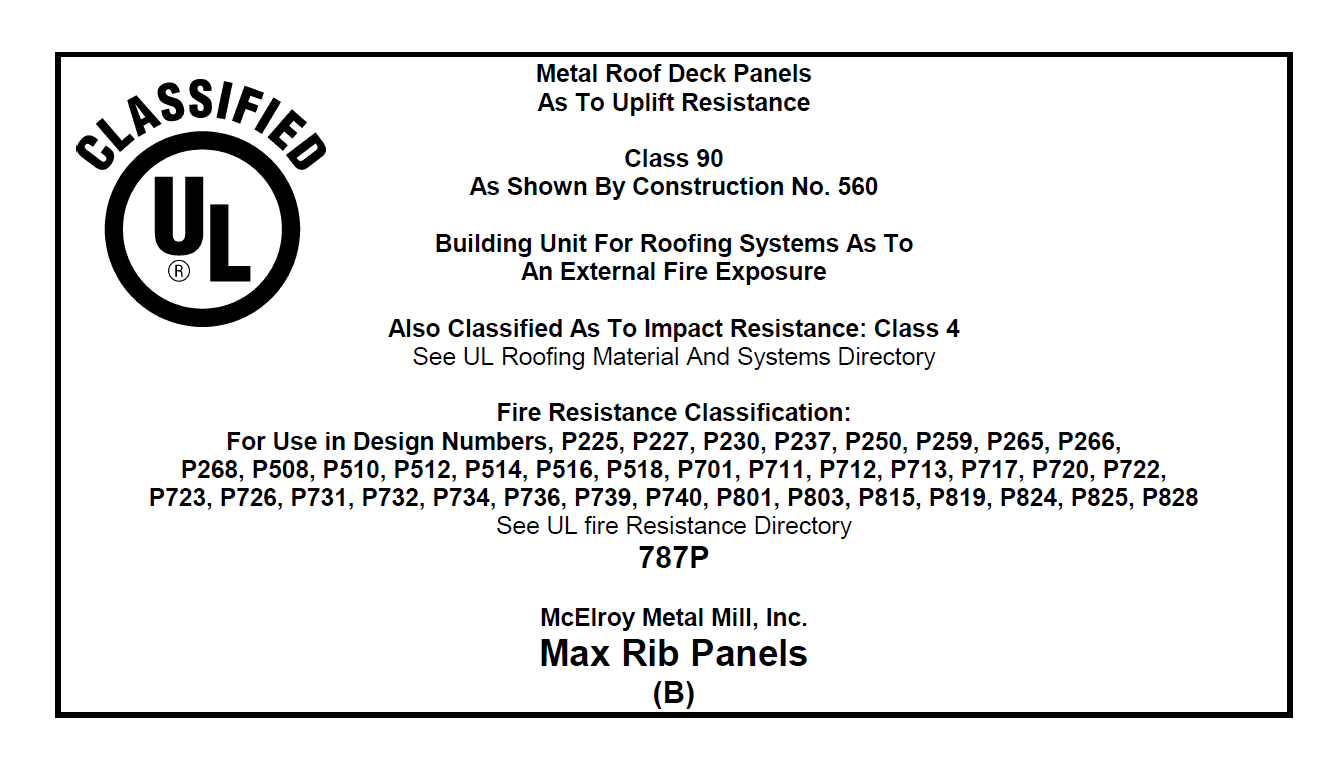

Determining if your roof is (or isn’t) impact-resistant can take a couple of different paths. UL does not recognize a panel as being UL 2218 classified for metal roofing unless the label shown below is attached.

You can also visit the manufacturer's website where you purchased the material and look for completed testing information. For example, McElroy Metal offers this information in the Downloads section of our website and on individual product pages, as shown below.

.png?width=1600&height=1600&name=class-4-impact-resistance-max-rib-metal-roofing%20(1600%20x%201600%20px).png)

Whether assessing your current roof or selecting materials for something new, please consider the benefits of investing in a Class 4 product and make the best choice for your project.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.