Installing Metal Buildings 101

Have you ever wondered how metal buildings get built so fast? Here at McElroy Metal, we’re specialists in metal building components and have been at it for over 57 years. When it came time to expand our corporate facility, we thought it would be a great idea to document the process.

This way you can find out what it takes to quickly build a durable, energy-efficient, and great looking metal building. So without further ado, let’s dive deeper into our construction process.

Metal Building Components

First and foremost, it’s important to go over the various components that make up a metal building.

The key structural members that support the building's sub-structural components are called the main frames. They support the roof sub-structural members, called purlins, and wall members called girts. The purlins and girts are both produced in McElroy’s manufacturing facilities.

So how exactly are the main frames bolted in? Good question! Prior to the main frames arriving on-site, the concrete foundation is poured and anchor bolts are set in the curing concrete. Later, when the metal building contractor arrives with the main frames, construction of the structure can begin immediately by attaching the main framing to the anchor bolts.

So how exactly are the main frames bolted in? Good question! Prior to the main frames arriving on-site, the concrete foundation is poured and anchor bolts are set in the curing concrete. Later, when the metal building contractor arrives with the main frames, construction of the structure can begin immediately by attaching the main framing to the anchor bolts.

Once all of these parts come together, the metal building is erected in no time. While this lightning-fast speed is impressive, you may wonder how everything stays together. After all, it seems like everything is so light and open at this point.

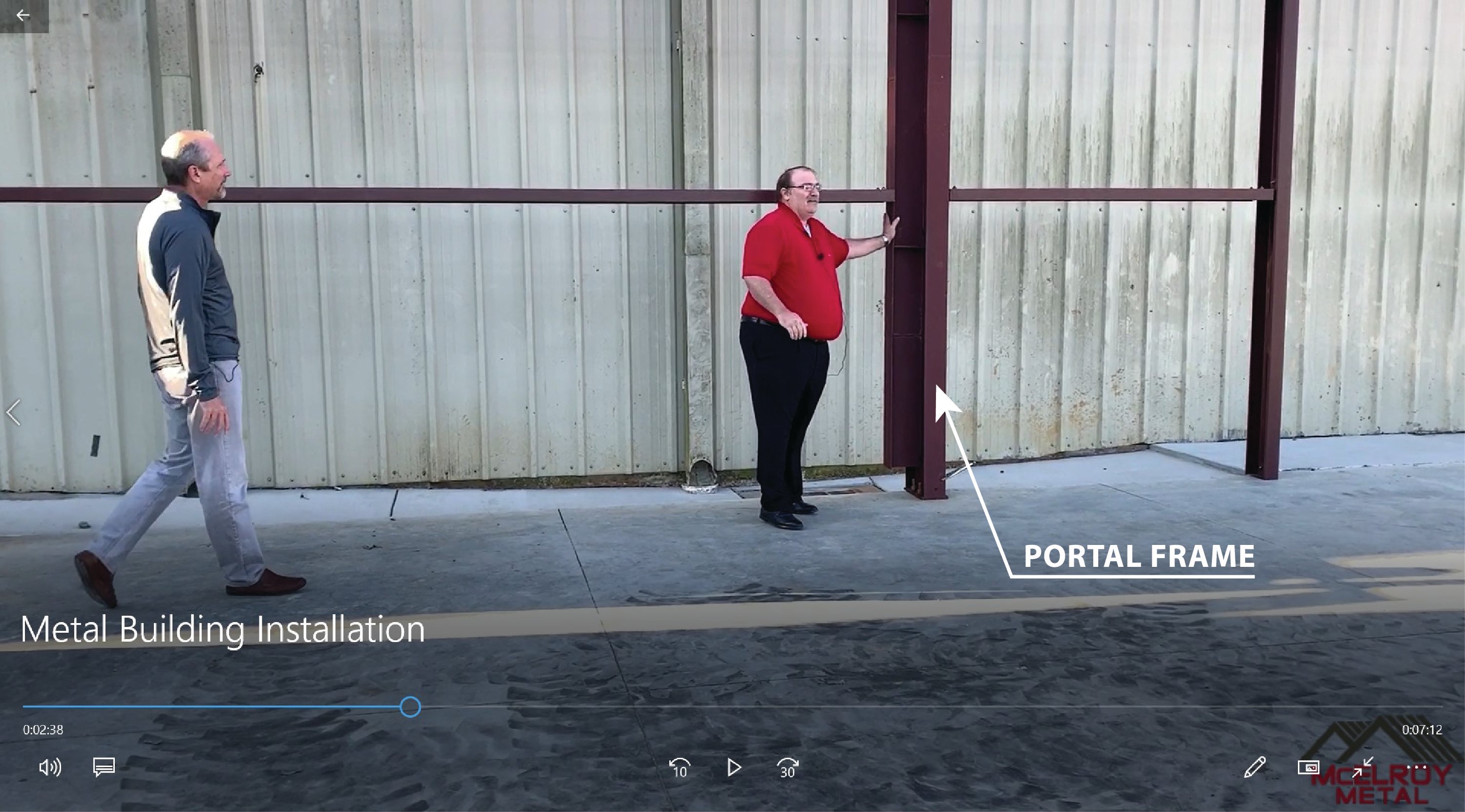

The answer is it all comes down to the bracing.

Cable bracing in the roof helps transfer longitudinal loads (loads acting perpendicular to the end walls) to the portal frames or sidewall bracing. Portal frames or sidewall bracing on the side walls transfer these loads to the foundation.

The main frames, since they are moment resisting frames, can transfer the lateral loads (loads acting perpendicular to the side walls) to the foundation directly with no additional bracing needed.

Cees and Zees

Cees and zees are often referred to as secondary substructural components. Cees and zees are attached to the main frames and together they provide overall support for the structure and a connection point for wall and roof panels.

The building designer will choose whether they’d prefer to use a cee or zee, which both come in a wide variety of sizes and gauges. Ultimately, the size of the component depends on how much load they need to resist, which is typically a decision made by the project engineer based on local code requirements.

Window and Door Framing

Window and Door Framing

There must be framing applied to any space where there will be a window or door.

The windows are usually a pre-formed unit that pops right into the designated opening and gets mechanically attached. The doors are similar and many are self-framing doors which eliminates the need for additional cold-form framing.

The door frames will be installed in the specified locations and attached to the sub-structural members.

Green Span Profiles Insulated Metal Panels

McElroy Metal installed Green Span Profiles insulated metal panels on the walls and roof. The Impression® wall panels feature a tongue and groove that enable panels to slide into one another.

McElroy Metal installed Green Span Profiles insulated metal panels on the walls and roof. The Impression® wall panels feature a tongue and groove that enable panels to slide into one another.

Green Span Profiles insulated metal panels feature factory-applied sealant that weather seals the panels together. Full disclosure, McElroy Metal is a joint venture partner in Green Span Profiles.

Insulated Metal Panels (IMP’s) on the wall provide the finished exterior, interior and insulation all in one panel. In the case of this building, McElroy decided to leave the IMP's and metal building framing exposed on the interior, which eliminated the need for drywall.

In addition, Green Span Profiles insulated metal panels offer continuous insulation. They also come with optional embossing, giving them a unique, textured appearance.

RidgeLine Roof Panel

RidgeLine Roof Panel

McElroy Metal also takes great pride in its use of Green Span Profiles' RidgeLine, the IMP industry’s premier insulated standing-seam roof panel. RidgeLine's most noteworthy advantage is its 238T Symmetrical Standing Seam.

With RidgeLine, a contractor can simply lay the panels out and slide them into place. There’s no need for rolling heavy panels into place as required for vertical leg IMP roofing systems.

When properly designed, engineered and erected, a metal building can be up and running very quickly, which enables a quick move-in and utilization of the space.

If you have further questions about the process, we encourage you to reach out to us. We’d be more than happy to go over any specifics and discuss our product offerings.

Contact us today for more information!

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.