Daylighting a metal roof: An overview of natural daylighting benefits

Daylighting is the use of glazing to allow natural light into spaces, often replacing the use of artificial light. By glazing, we typically mean glass or plastic. This article will focus primarily on plastic, specifically polycarbonate.

Daylighting Options

Daylighting Options

From a plastic or polycarbonate perspective, there are two types of daylighting options, top lighting (skylights and roof lights) and side lighting. Side lighting is referred to as clerestory windows and traditionally occurs in vertical wall applications.

Adding a reflective shelf in front of the glazing is called shelf lighting and is also a popular solution to introduce more daylight into the building. Traditionally, daylighting has been used in agricultural applications where electricity is unavailable or simply is not cost-effective in areas such as loafing sheds, fertilizer storage buildings, animal confinement buildings, and so forth.

Today, in addition to those traditional agricultural uses, natural daylighting is used in high-end architectural projects, retail facilities, hospitals, schools, offices, warehouses, and more.

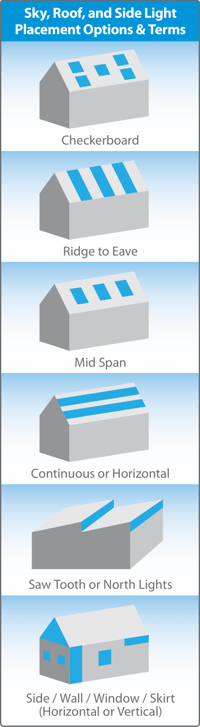

There are many configurations available for skylights, including a checkerboard style, ridge-to-eave, mid-span, continuous or horizontal, sawtooth or northern lights, or side lighting (vertical or horizontal) (See fig. 1 on the right).

When determining where to place sidelights, a north or south-facing wall provides more even lighting for longer portions of the daylight hours. In contrast, east and west-facing sidelights often have harsh glares and provide light for only short portions of the day.

Installation

Installing polycarbonate skylights or sidelights is relatively easy. The corrugated panel installation is virtually the same as any corrugated metal roofing or wall panel, with the exception of pre-drilling holes and the type of fastener used for proper installation.

Installing polycarbonate skylights or sidelights is relatively easy. The corrugated panel installation is virtually the same as any corrugated metal roofing or wall panel, with the exception of pre-drilling holes and the type of fastener used for proper installation.

The pre-drilling is necessary to allow for expansion and contraction, as polycarbonate expands and contracts at a different rate than metal. Rubber butyl tape, along with positive drainage, should alleviate any leakage concerns with skylights.

Leaks typically aren’t a concern with sidelight applications. Multi-Wall skylight or sidelight installation is equally as painless as the corrugated installation. There are a few additional accessories used in the installation: A snap HCX channel which is used to join two panels together in the longitudinal direction, breather tape for the top and bottom ends of the panel to keep out dirt and debris, and U channels which hide the unfinished sides and ends of the panels.

As is the case with the corrugated skylights, all fastener holes must be pre-drilled to allow for the thermal expansion of the material. Be sure to read the entire installation guide for Sunsky or Sunlite to ensure proper panel performance.

Life Expectancies & Warranties

Most polycarbonate manufacturers offer some type of warranty against discoloration, impact resistance, and hail for up to ten years. However, many polycarbonate installations have been in place for 20 years or more.

The impact resistance of polycarbonate is far superior to other daylighting options available on the market. Commercial warranties might be a bit different considering the product might be installed in an area where it could be subjected to chemical attack (i.e.waste treatment facility or harsh cleaning compounds).

It is important to note that UV inhibitors add to the life expectancy of polycarbonate panels. A co-extruded UV layer creates a more permanent bond and will not delaminate or crack. Go to Palram Americas website for more information.

Summary

The economic and societal impact of implementing natural daylighting far outweighs the use of artificial lighting. Daylighting not only saves energy but also produces positive results in human performance and moods.

So, while the electric bill is going down, the shoppers are buying more in retail facilities, the children are doing better on tests in schools, the factory workers are more productive, and the cooling load in the building is dramatically reduced.

Polycarbonate skylights and sidelights are among the most durable options available and allow for full-spectrum lighting to be introduced into the building to produce those positive effects, plus offer the opportunity for LEED® credits for your project.

As energy codes become more stringent, daylighting will be even more important in both new construction and renovations. Implementing daylighting in your current projects will put you ahead of the competition and provide valuable experience for the coming years.

About PALRAM Americas

With 50 years of expertise in the industry, PALRAM has established manufacturing, distribution, and sales operations across seven continents and 120 countries worldwide. Palram markets its products to the sign and graphics market, as well as to the commercial, industrial, residential, marine, and do-it-yourself construction markets.

Palram corrugated polycarbonate products are sold under the trade names SUNSKY® and SUNTUF®. Palram also offers the MetalMatch™ technology, allowing the use of SUNSKY polycarbonate panels for daylighting options with virtually any metal profile available. SUNSKY is offered in a range of colors, including a soft white to eliminate glare.

Palram also offers SUNLITE®, a multi-wall polycarbonate sheet for skylights, roof lights, or side lighting applications.

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us. Looking for a distributor or contractor? Please click here to get started.