Posted by McElroy Metal ● May 9, 2019 12:05 PM

Solar Panels on a Metal Roof: The Ultimate Power Couple

In the world of roof panel systems, solar and metal make the ultimate power couple.

Individually, both systems are known for their durability, sustainability, and long-term cost savings. Together, they promise building owners a roof with a solid future—structurally, economically, and environmentally—particularly in states that offer tax incentives for using solar energy (see www.dsireusa.org).

An example is McElroy Metal’s retrofit installation and 500 kW solar project on its manufacturing facility in Peachtree City, GA. The solar project, which is part of a solar initiative program in Georgia, included the installation of 1,960 solar panels on both the plant roof and carport canopy. The power generated by the system will be sold back to Georgia Power, the regional utility provider.

The reroofing project involved replacing McElroy Metal’s 34-year-old metal roof, a galvanized R-panel, with its 238T symmetrical standing seam system. Unlike conventional standing seam systems, the 238T panel system has matching left and right seams that are joined with a mechanically seamed cap, allowing for easy removal and replacement of individual panels, according to Ken Gieseke, McElroy Metal’s vice president of marketing.

The reroofing project involved replacing McElroy Metal’s 34-year-old metal roof, a galvanized R-panel, with its 238T symmetrical standing seam system. Unlike conventional standing seam systems, the 238T panel system has matching left and right seams that are joined with a mechanically seamed cap, allowing for easy removal and replacement of individual panels, according to Ken Gieseke, McElroy Metal’s vice president of marketing.

“In general, metal is the best substrate for solar considering that the lifespan of both products match up perfectly,” said Andrew Proctor, senior project engineer of Inovateus Solar LLC, South Bend, IN, which served as general contractor on this project. “Solar on metal is not a new concept, but it is a growing trend. Solar installers are targeting metal roofs for the long lifespan and ease of installation.”

Gieseke and David Dodge, president of Paramount Metal Systems, Little Rock, AR, expressed the same sentiment. Paramount Metal Systems installed both the roofing and solar systems on the Peachtree City facility.

Gieseke and David Dodge, president of Paramount Metal Systems, Little Rock, AR, expressed the same sentiment. Paramount Metal Systems installed both the roofing and solar systems on the Peachtree City facility.

Dodge and his crews found the panel system easy to work with. “It’s a 2-ft panel so the erection was faster because we were covering more square feet per panel,” Dodge said, noting that his crews were able to cover an average 5,000 sq ft per day. “Everybody in the field was pleased with the installation. I don’t think it could have gone any better. The entire project took 6 weeks.”

The Paramount Metal Systems crew installed the 30,000 sq ft of retrofit metal roofing panels in about 8 days and needed another 2 1/2 weeks to install the solar panels.

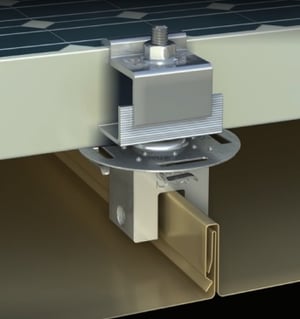

To attach the solar panels, three different S-5!® clamps were used—one for the 238T panel, one for an existing through-fastened panel on the facility, and a third for the existing standing seam panel on an office lean-to. The entire array was attached using the S-5-PV Kit, which allow attachment without penetrating the roof, rather than traditional rail or rack attachment methods. With the UL-listed S-5-PV Kit, modules are anchored in a way that provides a ground path in the module frame, practically eliminating the need for lugs or wire.

The panels were installed over the existing roof with McElroy’s patented 238T Retrofit Clip, a 3.5-in. standoff clip that elevates the height of the new roofing system to the top of the existing panels. The 238T Retrofit Clip sits between the ribs of the existing roof, eliminating the need for sub-framing, greatly reducing material and labor expense.

The panels were installed over the existing roof with McElroy’s patented 238T Retrofit Clip, a 3.5-in. standoff clip that elevates the height of the new roofing system to the top of the existing panels. The 238T Retrofit Clip sits between the ribs of the existing roof, eliminating the need for sub-framing, greatly reducing material and labor expense.

The tall clip stands just above the existing panel’s major ribs, allowing for the insulation. For this project, foam insulation provided increased R-value as well as support for the new roof panels.

When it comes to installing solar on metal, Gieseke noted that the economies of scale are ideal when both solar and metal panels are installed at the same time. With good project management and the use of high-grade, easy-to-install metal panels, the process can run very smoothly. “This project actually ran like clockwork,” Gieseke said.

PROJECT: McElroy Metal’s retrofit installation and solar project

LOCATION: Peachtree City, GA

CONTRACTOR: Inovateus Solar LLC, South Bend, IN

METAL INSTALLER: Paramount Metal Systems, Little Rock, AR

MCA-MEMBER MANUFACTURER: McElroy Metal, Bossier City, LA

MATERIALS: McElroy Metal’s 238T symmetrical standing seam system

DATE OF COMPLETION: December 2013

About McElroy Metal

Since 1963, McElroy Metal has served the construction industry with quality products and excellent customer service. The employee-owned components manufacturer is headquartered in Bossier City, La., and has 14 manufacturing facilities across the United States. Quality, service and performance have been the cornerstone of McElroy Metal’s business philosophy and have contributed to the success of the company through the years. As a preferred service provider, these values will continue to be at the forefront of McElroy Metal’s model along with a strong focus on the customer.

Topics: Company, Metal Roofing, Standing Seam Systems, Solar, Commercial, R-Panel, 138T and 238T, Case Study

Comments on this article:

Scroll down to the bottom to submit a comment and join the conversation. Need help or have a question? Please contact us.

%20(002).png)